MSS Line

The MSS line is equipped with a tilting head which can be used flexibly, depending on variant: In the pneumatic version, the pad can be turned by 90°, while for the electric version, the pad’s angle can be adjusted freely between 0° and 90°. This enables the machine to print on vertical surfaces, especially in production lines where the print object cannot be turned or can only be turned with a lot of effort. The pad printing machines can be operated very conveniently from the rear side, guaranteeing comfortable handling and optimal accessibility. It is not necessary to pull out or turn the machine. In the pneumatic version, position correction is performed mechanically via the cliché holder. For the electric variant, the print position is adjusted electronically using a display. Multiple image positions on the cliché can be controlled in this way. In addition, the height, the contact angle and the length of time for which the pad remains on the product can be flexibly adjusted. Various special versions are also available, including the particularly compact MSS 60. The system is controlled intuitively via a user-friendly touchscreen display.

Applications

The MSS line has been specially designed for systems where the printing piece cannot be turned and horizontal printing is required – for example, on car brake linings which are transported on a conveyor belt and have to be printed with precision on their front face. Unlike the competition, the MSS can be completely

retooled and operated from the rear side.

Inkwell

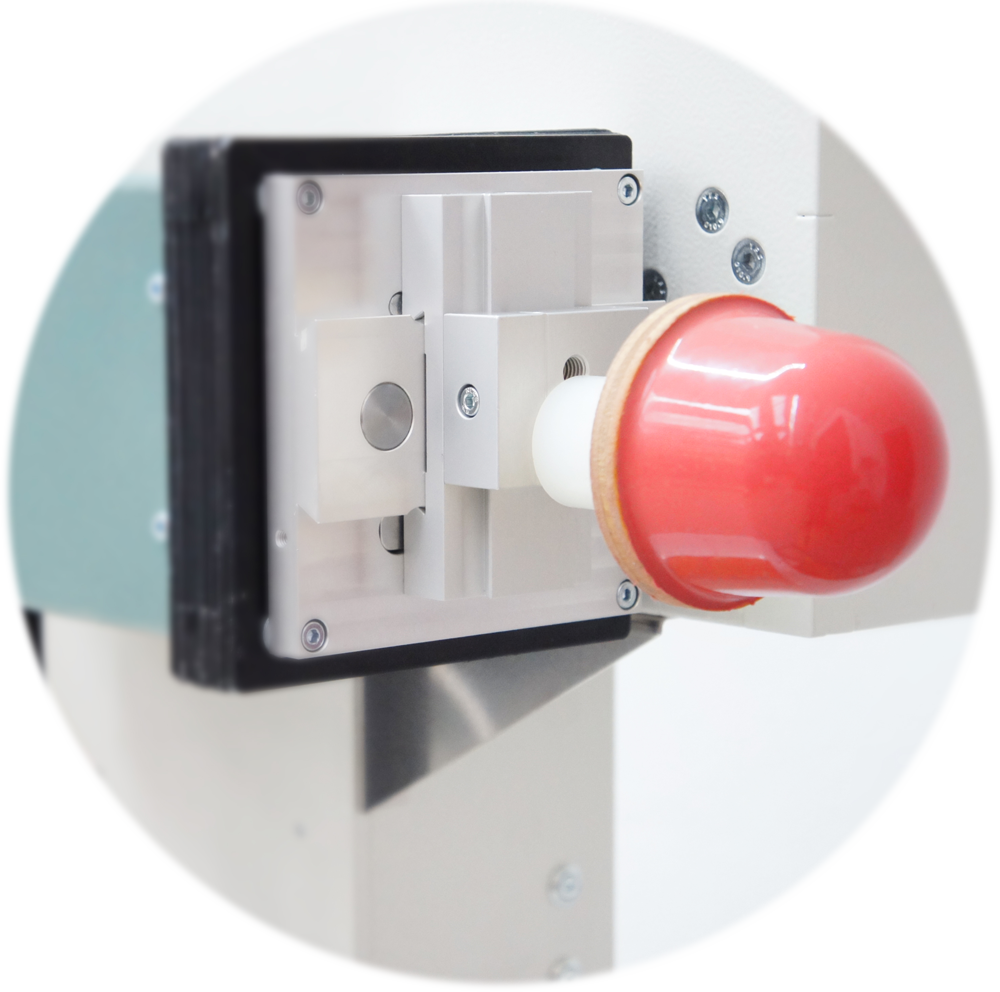

The MSS line prints a single colour and features a closed inkwell. The maximum cup size is 120 mm in diameter. A pneumatically reinforced cup holder is available if required. Ink viscosity is regulated automatically with the optional Viscomat. A special variant enables the use of up to three ink cups, in order to print several N-up layouts at once or in multiple colours.

Pad positioning

In the pneumatic version, position correction is performed mechanically via the cliché holder. The fixed turning angle of the pad of 90° can be fine-tuned within a limited range with the aid of an optional rotary button. In the electric variant, the print position is adjusted electronically via a display. Several image positions on the cliché can be controlled in the process. The height, contact angle and the time for which the pad remains on the product can also be adjusted freely and individually.

Operation, software and interface

Operation is performed through a graphic touchscreen display. Using an extension, this display can also be fixed on the machine’s exterior if required. Printing parameters can be adjusted in simple steps with the help of user-friendly visual representations. In addition, the settings can be adjusted. The MSS line is equipped with a digital interface for communication with the system. The larger tilting-head machines can

be optionally equipped with Industrial Ethernet or OPC-UA.

Accessories

For standalone operation within a system, we recommend at least pad cleaning control and the Viscomat. The pad cleaning control function informs the operator when the end of the cleaning tape is reached. The optional Viscomat automatically regulates the viscosity of the ink during the printing process. Both functions serve to guarantee a high, consistent printing quality over long running times.

MAXIMUM ROTATION – IN PRECISION

Introduction video

System options

As part of an overall system with conveyor belt

Two-colour printing with mirrored machine

Rotary indexing table in combination with MS line

Robot loader with two opposing machines

Downloads

MSS-Line

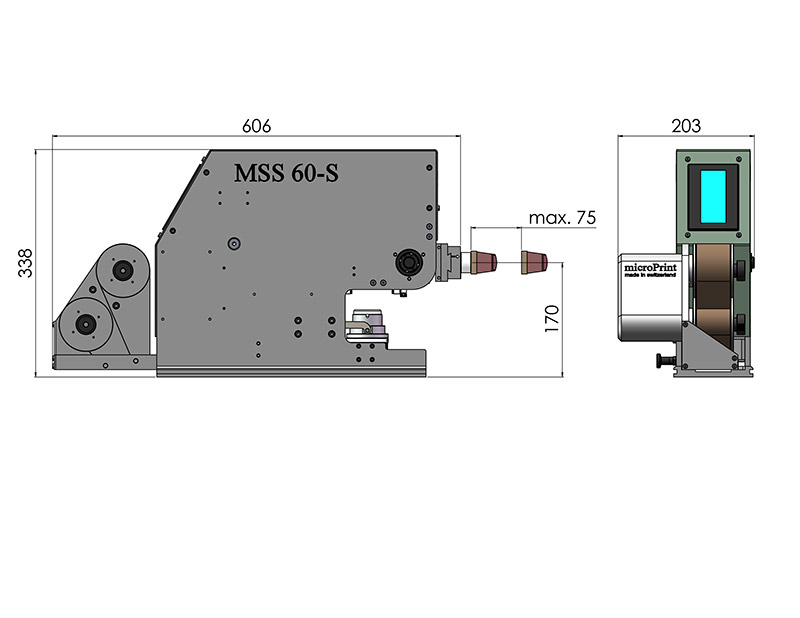

| Machine types | MSS 60 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,800/1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 60 x 120 x 10 |

| Ink cup [number x Ø in mm] | 1x45 / 1x56 |

| Print image max. [Ø in mm] | 35 / 46 |

| Pad stroke – force [N] | 170 |

| Pad stroke – travel distance max. [mm] | 75 |

| Pad projection max. [mm] | 90 |

| Pad cleaning | Integrated: 50 mm wide |

| Interfaces | digital interface |

| Thinning system | Special variant |

| Weight without base [kg] | approx. 18 |

| Air consumption [l/min] | 20 |

| Power supply | 110 – 240V, 50/60Hz |

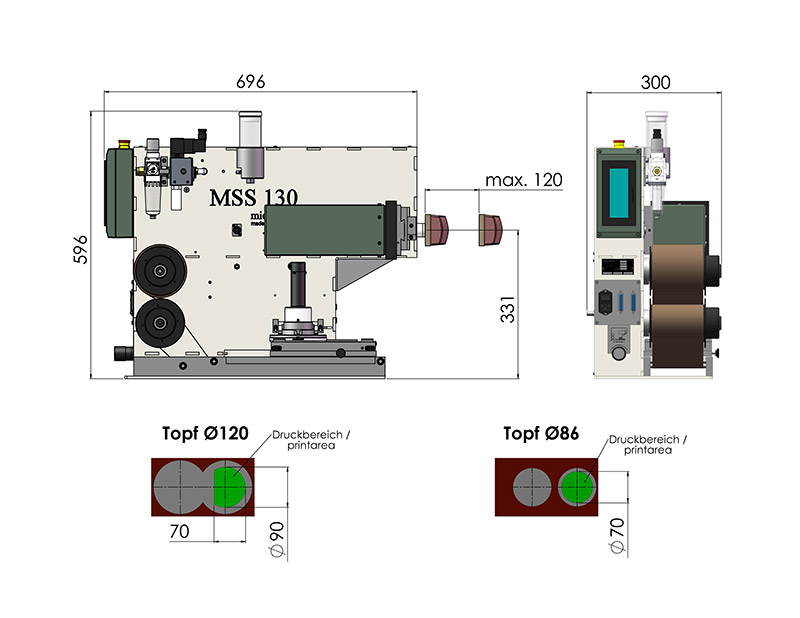

| Machine types | MSS 130 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,800/1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 130 x 230 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x86 / 1x120 |

| Print image max. [Ø in mm] | 76/110 |

| Pad stroke – force [N] | 480 N |

| Pad stroke – travel distance max. [mm] | 120 mm |

| Pad projection max. [mm] | 90 |

| Pad cleaning | Integrated: 115 mm wide |

| Interfaces | digital interface |

| Thinning system | optional |

| Weight without base [kg] | approx. 60 |

| Air consumption [l/min] | 115 |

| Power supply | 110 – 240V, 50/60Hz |

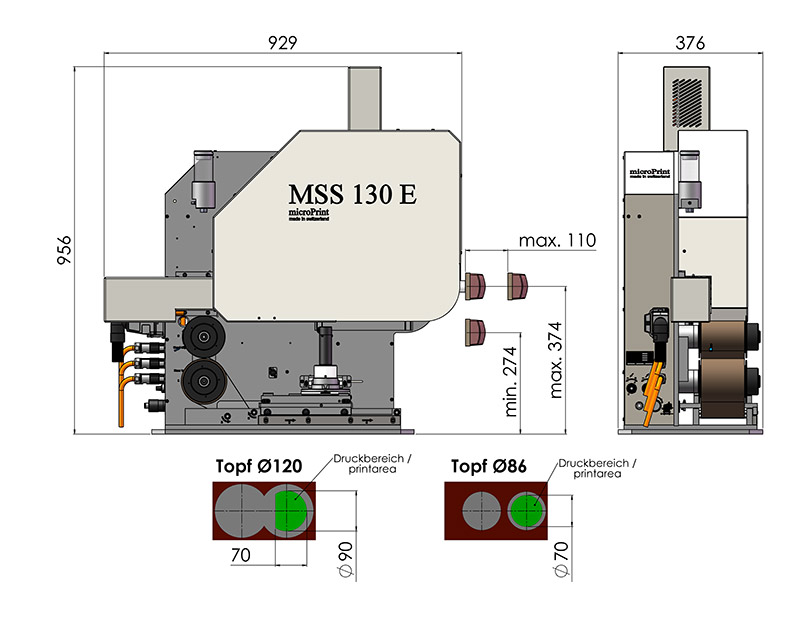

| Machine types | MSS 130E |

| Number of colours | 1 |

| Speed [cycles/h] | 1,800/1,200 with pad cleaning |

| Drive – pad stroke | electric with servo motor |

| Cliché sizes max. [mm] | 130 x 230 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x86 / 1x120 |

| Print image max. [Ø in mm] | 76/110 |

| Pad stroke – force [N] | 1.200 |

| Pad stroke – travel distance max. [mm] | 110 |

| Pad projection max. [mm] | 0 – 90 |

| Pad cleaning | Integrated: 115 mm wide |

| Program memory size | 200 |

| Interfaces | optional: Ethercat, Profinet, Ethernet IP, OPC-UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 135 / Switchboard display approx. 35 |

| Air consumption [l/min] | 10 |

| Power supply | 3P, 400/480V, 50/60Hz |

| MSS 130E | |

| |

| Download detailed drawing as PDF | |