LCN-Line

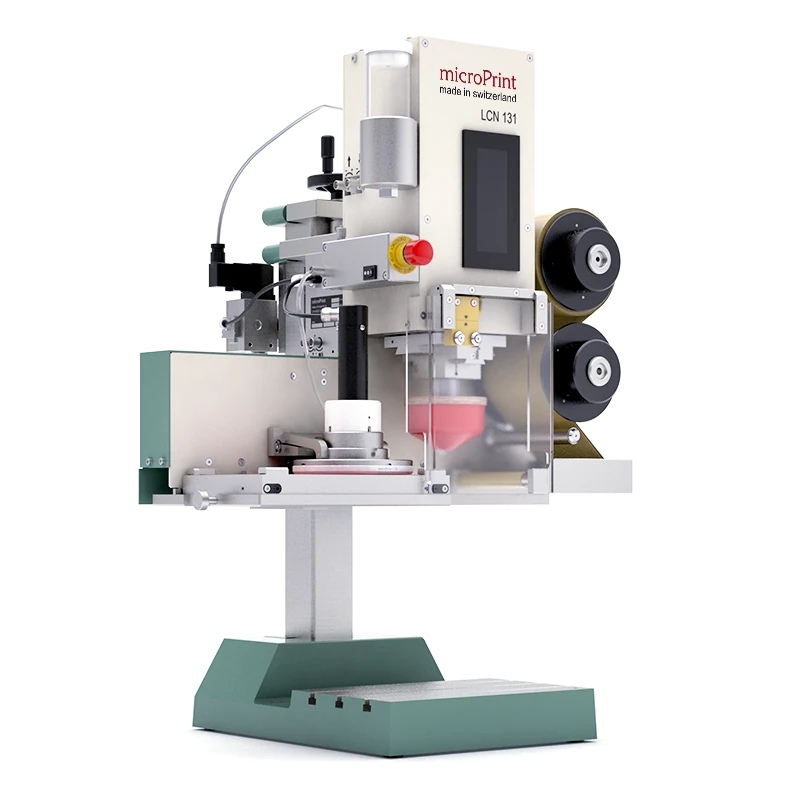

The LCN line features compact pneumatic machines for single-colour pad printing that are

equipped with closed inkwells. LCN line machines are suspended above the print object.

Using the adjustment option on the cliché holder, the X and Y directions and also the angle

of the printing position can be adjusted precisely.

The integrated pad cleaning system works at the same height as the cliché slide, thereby reducing

the travel distance of the pad. This special arrangement makes the cliché, pad and cleaning tape

readily accessible and thus very easy to reach.

Operation is performed through the graphic monochrome touchscreen display.

The special feature of this machine series is its sublevel printing function,

which also allows very large parts to be printed.

Applications

The LCN line machines were designed as a single-colour printing solution to be installed into larger systems. Their compact design reduces the space required for pad printing within the overall system – without compromising on accessibility. Large components can be printed as the suspended machine is capable of sublevel printing. A special version also offers parallel printing of several N-up layouts at once.

Inkwell

Pad positioning

Operation, software and interface

The pad printing machine features a digital interface that enables reliable communication with other devices and control systems. As a result, the machine can be seamlessly integrated into existing production environments. Profinet, Ethernet/IP or EtherCAT are also available as options for system communication, which enables complete remote control of the printing machine.

Accessories

For standalone operation within a system, we recommend at least pad cleaning control and the Viscomat. The pad cleaning control function informs the operator when the end of the cleaning tape is reached. The optional Viscomat automatically monitors and regulates the viscosity of the ink during the printing process. Both functions guarantee a high, consistent quality of the printing process over long running times.

Maximum compactness – in production

Introduction video

System options

As part of an overall system with conveyor belt

Special variant for multiple uses

Rotary index table for pre- & post-treatment

Printing on large components

Examples

Downloads

LCN Line

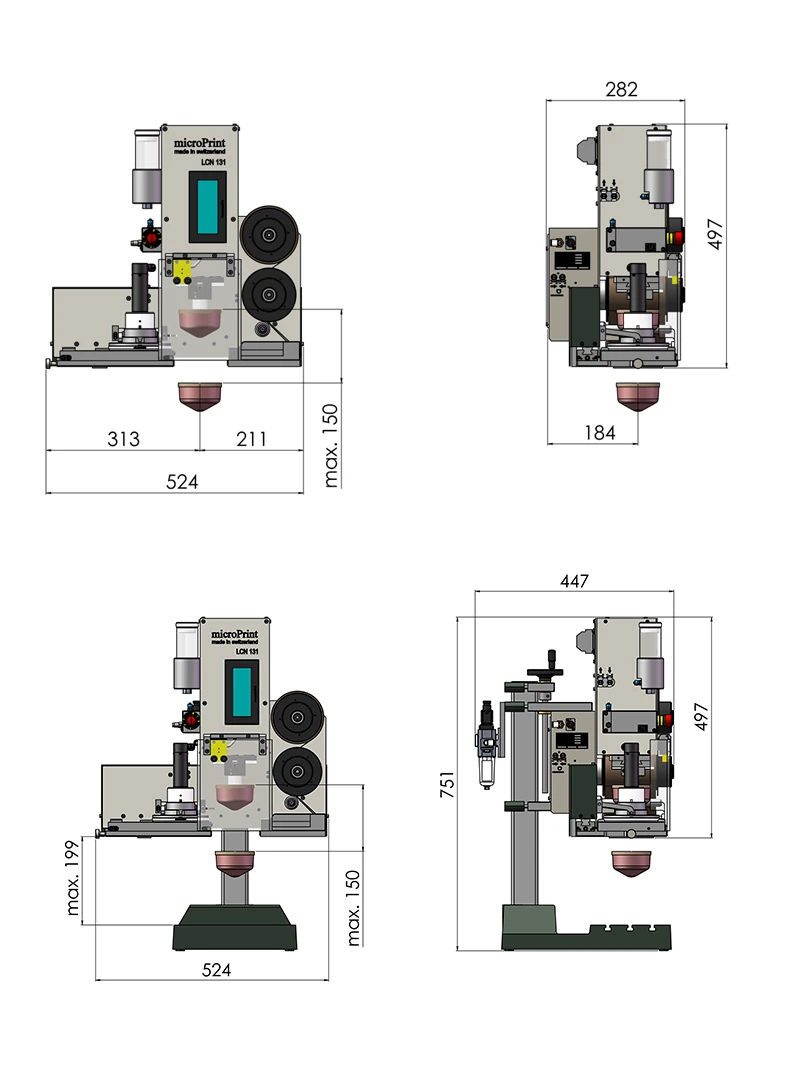

| Machine types | LCN 131 |

| Number of colours | 1 |

| Speed [cycles/h] | 2,000/1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 130 x 230 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x56 / 1x70 / 1x86 / 1x120 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 480 |

| Pad stroke – travel distance max. [mm] | 180 |

| Pad cleaning | Integrated: 115 mm wide |

| Thinning system | optional: 1 connection |

| Weight without base [kg] | approx. 32 |

| Air consumption [l/min] | 76 |

| Power supply | 110 – 240V, 50/60Hz |

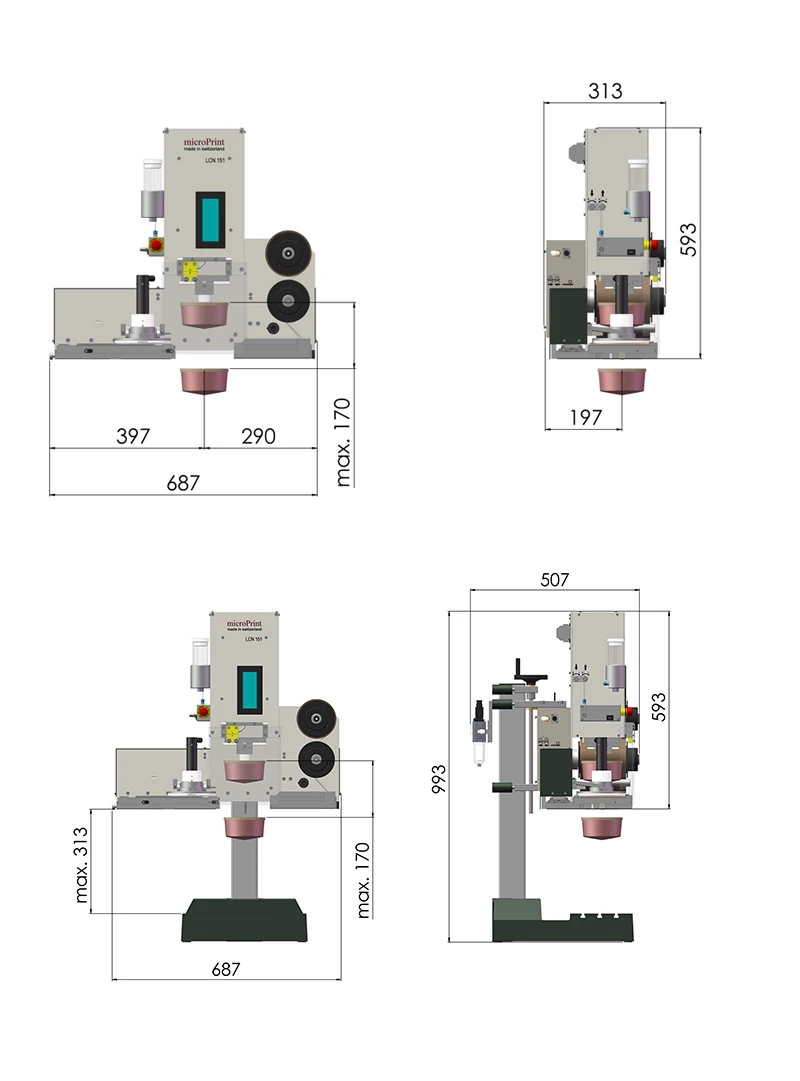

| Machine types | LCN 151 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,800/1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 150 x 300 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x120 / 1x140 |

| Print image max. [Ø in mm] | 110 / 130 |

| Pad stroke – force [N] | 1.100 |

| Pad stroke – travel distance max. [mm] | 170 |

| Pad cleaning | Integrated: 138 mm wide |

| Thinning system | optional: 1 connection |

| Weight without base [kg] | approx. 61 |

| Air consumption [l/min] | 136 |

| Power supply | 110 – 240V, 50/60Hz |