Pad printing machines

Smart line

Smart 130 | Smart 250

The Smart line includes cost-effective pneumatic pad printing machines for up to three colors, available with open or closed ink cups. The print image is mechanically positioned using a cross table. It is an ideal entry-level model for promotional and industrial printing applications.

Up to three colours

Max. cup size 120mm

X-Y position adjustable by means of cross table

Pneumatic rotation around 1 axis

-

-

LCN Line

LCN 131 | LCN 151

The LCN line features compact pneumatic single-color pad printing machines that are suspended above the printing object. The print position can be adjusted via the cliché holder. These machines are specifically designed for integration into larger systems.

Single- colour

Max. cup size 140mm

X-Y position adjustable by means of cliché holder

-

Automatic viscosity control

-

MS Line

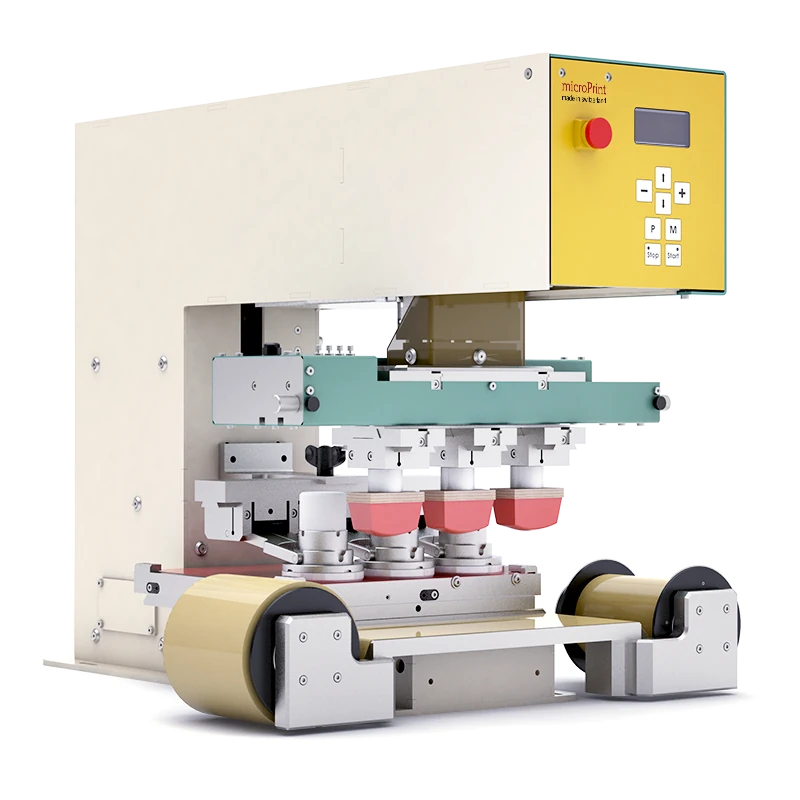

MS 130 | MS 150 | MS 250 | MS 300

The MS line offers pneumatic pad printing machines for up to four colors, with options for open or closed ink cups or transverse doctor blades. Print position adjustments are made mechanically on the machine. It is suitable both as a standalone workstation and for integration into systems for a wide range of printing tasks.

Up to 4 ink cups or transverse doctoring units

Max. cup size 140mm

Pneumatic & electric pad shuttling

Electric rotation around 1 axis

Automatic viscosity contro

Camera control

MSS-Line

MSS 60 | MSS 130 | MSS 130E

The MSS line consists of single-color pad printing machines with a tilting head. The pneumatic version allows a 90° rotation, while the electric version offers a freely adjustable angle from 0° to 90°. This enables direct printing on vertical surfaces – ideal for production lines where the workpiece cannot be rotated. The machines are operable from the rear, with no need to pull them out.

Single-colour

Max. cup size 120mm

Tilting-head system for vertical printing

-

Automatic viscosity control

-

ML Line

ML 350 | ML 350E | ML 500 | ML 500E

The ML line provides multi-color pad printing machines with electric positioning, closed ink cups or transverse doctor blades, and optional pneumatic or electric pad stroke. Print positioning is controlled via a touch display, and the printing process is fully programmable. It is ideal for complex parts and demanding applications.

Up to 7 ink cups or transverse doctoring units

Max. cup size 160mm

X-Y position electrically adjustable

Electric rotation on 2 axes

Automatic viscosity control

Camera control & positioning

Modul Line

Modul 130 | Modul 130E | Modul 170 | Modul 170E | Modul 220 | Modul 220E

The Modul line includes single-color pad printing machines with electric positioning, closed ink cups, and optional pneumatic or electric pad stroke. Print positioning is controlled via a touch display, and the printing process is fully programmable. These machines can be combined into large, high-speed multi-color systems, making them ideal for complex parts and the most demanding requirements.

Single- colour

Max. cup size 200mm

X-Y position electrically adjustable

Electric rotation on 2 axes

Automatic viscosity control

Camera control & positioning

Specialized machines

Although we already offer a wide range of pad printing machines, not all tasks in pad printing can be covered with them. Specific requirements, such as spatial constraints, particularly large or unusual products, or additional technical challenges, may make it necessary to develop a custom-made pad printing machine. Do you have such a requirement that cannot be easily met with standard machines? No problem! We have a wide selection of proven machines, and if none of them meet your needs, we can develop a custom pad printing solution for you. In doing so, we rely on tried-and-tested components to manufacture a machine that is precisely tailored to your requirements. Here is a small selection of our solutions.