Smart line

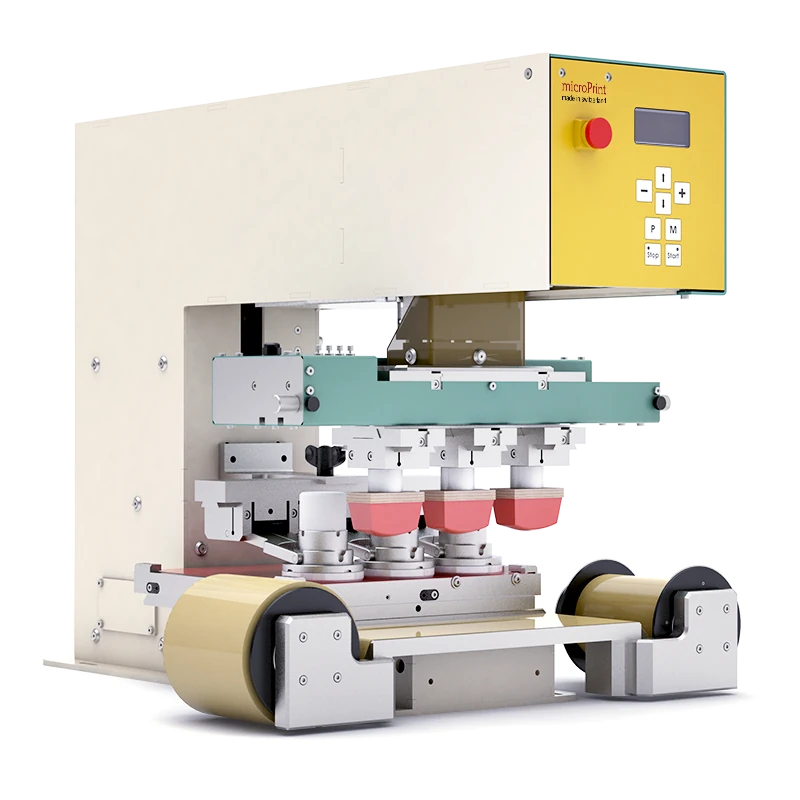

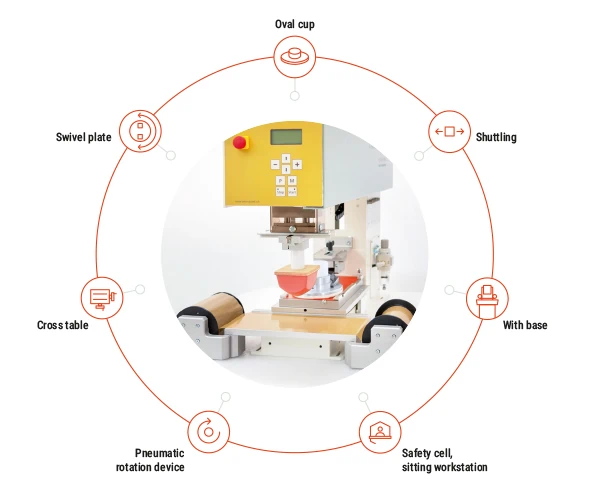

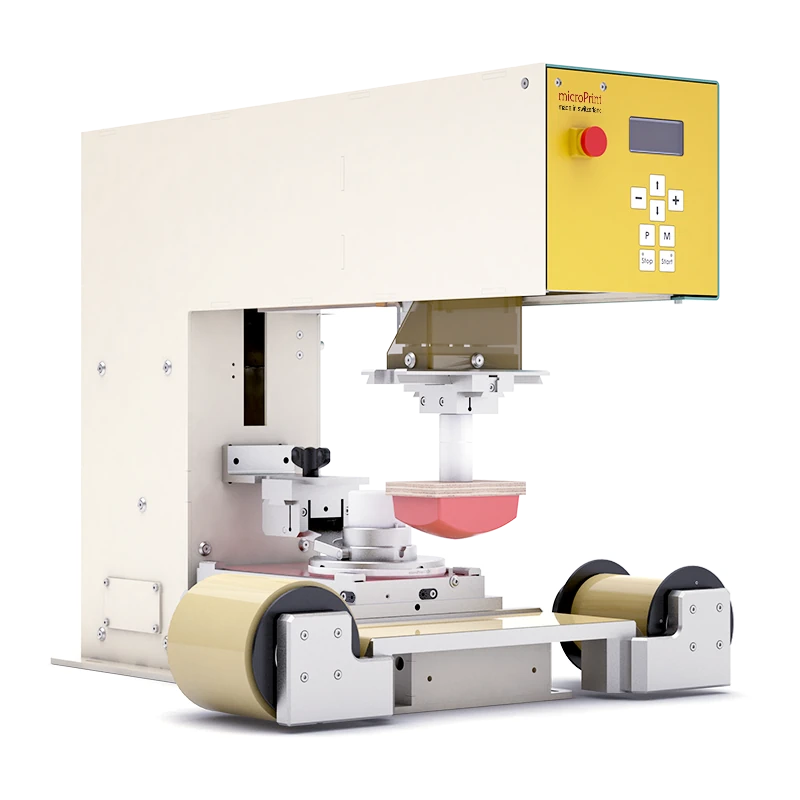

The Smart line features conventional pneumatic pad printing machines that can print up to three colours. It is available with open or closed inkwells. The print image is positioned mechanically by means of a cross table. The pad printing machines offer manifold possibilities for expansion: among other things, they can be equipped with pneumatic rotation or shuttling of the print object. They are operated using a membrane keypad with a text display.

This cost-effective line is ideally suited as an entry-level model for commercial printing and industrial applications. Thanks to their design with a double cylinder, the machines in the Smart line achieve a particularly high printing force. The resulting weight reduction means that higher speeds can be achieved.

Applications

The Smart line pad printing machines can be used primarily as manual workstations. They are available both as table-top models and with a stand. They are ideal for simple printing tasks, such as printing

logos, text or graphics onto products in up to three colours. Due to their high printing force, even large images or N-up layouts are printed reliably.

Inkwell

Using the closed inkwell system, printing procedures with up to three colours are possible with a cup size of 70 mm. If cup sizes 86 mm and 120 mm are used, a maximum of two colours can be printed. Alternatively, for longer print images, an oval cup can be used. Two cliché sizes are available: a large single cliché or two separate clichés with their own cliché holders. On request, Smart line machines can also be equipped with open inkwells.

Pad positioning

The pad moves pneumatically with fixed stops. The print object must be positioned using a cross table.

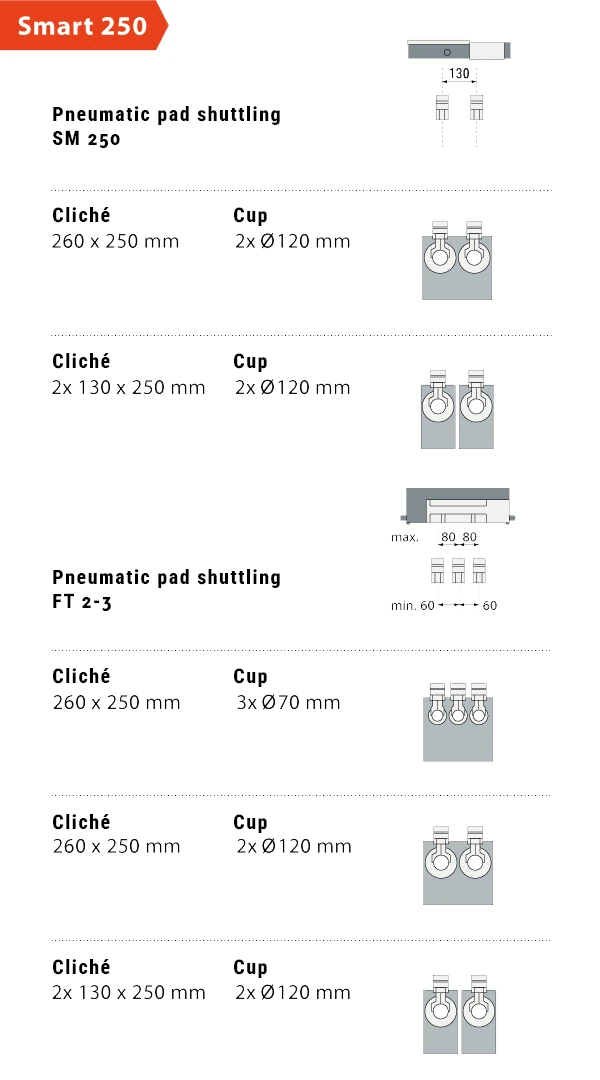

The pad position can be freely adjusted mechanically by means of two dove tails. Pneumatic 2- or 3-colour pad shuttles are available for multi-colour printing. The 3-colour pad shuttle dispenses the ink at the centre.

When printing two colours and using two separate cliché holders, the print image can be positioned freely in the X and Y direction, as well as at an angle.

Parts handling

The print object is manually inserted into the holder and positioned via the cross table. If printing two colours with a pad combination is not possible due to an interfering edge, 2-colour printing using a single pad is also possible. Multi-sided printing on the print object is made possible by pneumatic rotation in one axis. Using a swivel plate, the next part can already be inserted during the printing process.

Operation, software and interface

The Smart line is operated by means of a membrane keypad with a text display. It also features a digital interface, which enables simple automation functions or the connection of additional devices.

Various helpful special functions are available to simplify the setup of the machine, such as mixing the ink by moving the doctoring cup, printing on the cleaning tape or viewing the print image on the pad.

Accessories

For an optimised workflow, we recommend pad cleaning. A base with a height-adjustable table or for table-top machines and a cross table round off the workstation. If required, it can also be equipped with a safety cell. Here, either a light barrier or two-hand operation is available.

ONE SOLUTION – MANY POSSIBILITIES

Are you looking for a cost-efficient solution to meet your needs?

The Smart line offers a broad range of configurations to meet your specific needs, ensuring maximum precision, efficiency and versatility.

Introduction video

System options

Available without pad cleaning

Swivel plate

Downloads

Smart line

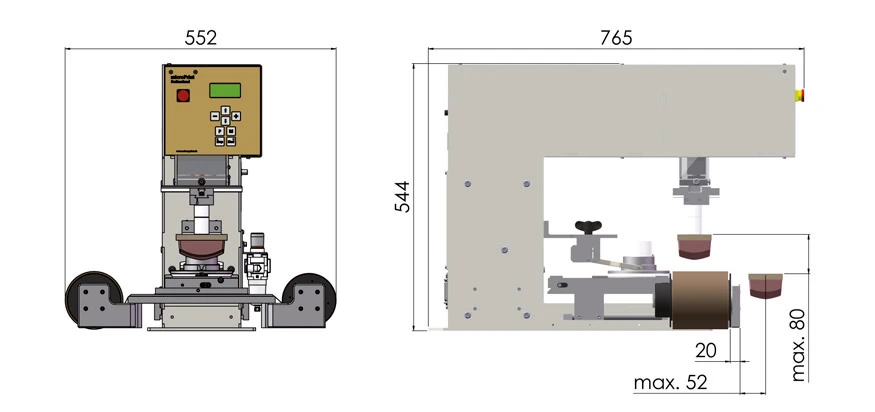

| Machine types | Smart 130 |

| Number of colours | 1 |

| Speed [cycles/h] | 2.100 / 1.700 / 1.200 mit Tamponreinigung |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 130 x 250 x 10/0,5 |

| Cliché sizes max. open [mm] | 150 x 120 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x56 / 1x70 / 1x86 / 1x120 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 960 |

| Pad stroke – travel distance max. [mm] | 80 |

| Pad projection max. [mm] | 69 |

| Pad cleaning | optional: 115 mm wide |

| Control | Microprocessor |

| Thinning system | - |

| Weight without base [kg] | approx. 60 |

| Air consumption [l/min] | 116 |

| Power supply | 110 – 240V, 50/60Hz |

| Smart 130 | |

| |

| Download detailed drawing as PDF | |

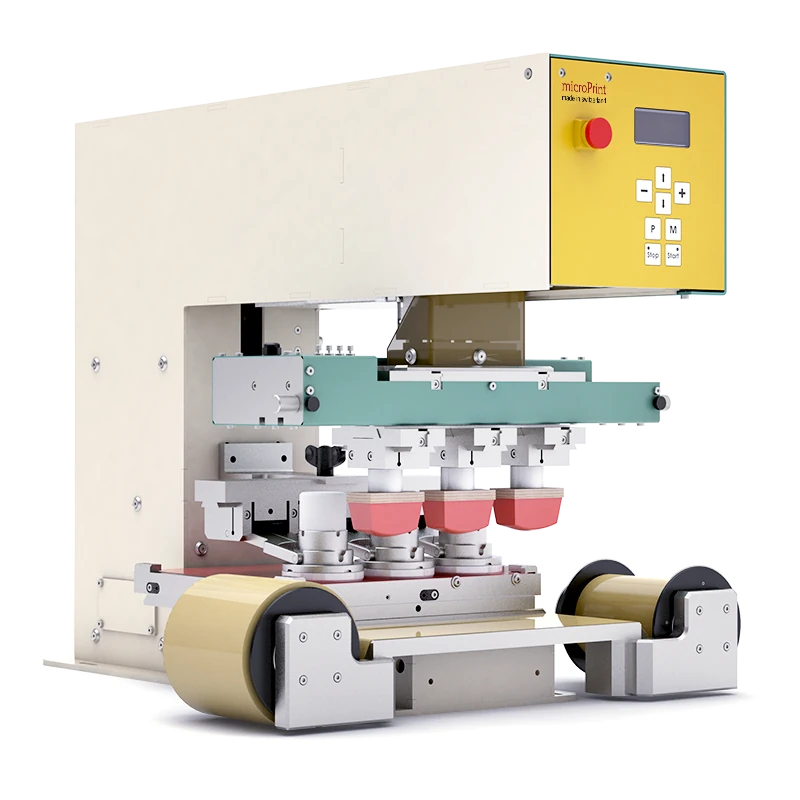

| Machine types | Smart 250 |

| Number of colours | 1 - 3 |

| Speed [cycles/h] | 2,100 / 1,700 / 1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 260 x 250 x 10/0,5 |

| Cliché sizes max. open [mm] | 250 x 120 x 10/0,5 |

| Ink cup [number x Ø in mm] | 3x70 / 2x86 / 2x120 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 960 |

| Pad stroke – travel distance max. [mm] | 80 |

| Pad projection max. [mm] | 69 |

| Pad cleaning | optional: 115 mm wide |

| Control | Microprocessor |

| Thinning system | - |

| Weight without base [kg] | approx. 60 |

| Air consumption [l/min] | 116 |

| Power supply | 110 – 240V, 50/60Hz |

| Smart 250 | |

| |

| Download detailed drawing as PDF | |