MS Line

The MS line includes conventional pneumatic pad printing machines which can print up to

four colours. It is available with either an open or closed inkwell, and as a transverse doctoring unit.

The printing position is mechanically adjusted on the machine. The system offers manifold possibilities

for expansion: among other things, it can be equipped with pneumatic or electric single-axis rotation

or a sliding shuttle for the print object. Operation is performed through the graphic monochrome touchscreen display. One special feature of this line is its ability to extend and retract the pad printing head. This makes the holder readily accessible, which guarantees easy and safe handling of the printing piece, as well as convenient visual inspection of the printed image on the piece while still inside the holder. There is also sufficient clearance for a loading robot.

Applications

Ideal for both simple and specialised printing tasks, the MS line can be used as a manual workstation or

integrated into a system. As it is possible to mechancally position the machines internally, they can also be used in systems without a cross table. Autonomous operation is ensured through monitoring of the cleaning belt and the microPrint Viscomat. The retractable pad printing head enables easy loading of the machine by robot. The print object can be turned or rolled either electrically or pneumatically. For printing longer images, either an oval cup or a transverse doctoring unit can be used.

Inkwell

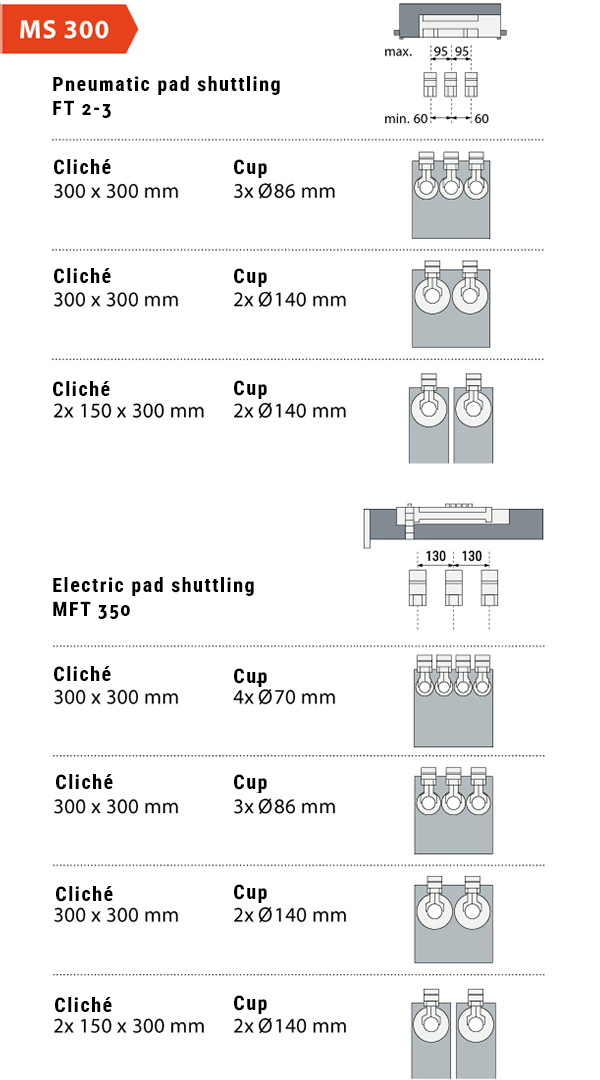

Printing of up to four colours is possible using 70 mm doctoring cups. When using maximum cup size of 140 mm, the number of colours is reduced to two. The machine also offers various intermediate sizes as well as combinations of different cups, oval cups, transverse doctoring units or open systems. The version for multiple colours can be ordered with a single large cliché or with two separately adjustable cliché holders. The travel length of the cliché can be mechanically adjusted and allows the use of different cliché sizes. The microPrint Viscomat autonomously controls the viscosity of the ink.

Pad positioning

The pad’s position is adjusted pneumatically along the Y axis. For ink uptake and distribution, it can also be mechanically positioned internally. The cliché holder is used to attain the pad’s X position and to adjust its angle. The pneumatic 3-colour pad shuttle always ensures a centred transfer of the print image, regardless of whether two or three colours are used. The electric pad shuttle can transfer up to four colours at any X position. Depending on requirements, the machine can work with either a combination of pads or a single pad.

Parts handling

It is possible to design the parts handling in a versatile manner. Along with pneumatic rotation and electric rotation around one axis, the use of pneumatic and electric part shuttling is also possible. A pneumatic unwinding device with a toothed rack allows printing on round objects. The print object can be fixated either with pneumatic clamps or using a vacuum. If desired, a parts recognition can be implemented here by means of vacuum fixtures or sensors.

Operation, software and interface

Operation is performed through the graphic monochrome touchscreen display. For larger systems, this can also be extended and fixed on the outside. Printing parameters can be set in simple steps with the help of user-friendly visual representations. The individual applications can be saved. The MS line is equipped with a digital interface for communication with a larger system.

Accessories

For autonomous operation inside a system, we recommend monitored pad cleaning and the use of the microPrint Viscomat. To accelerate production, the MS line can also be equipped with a swivel plate with two holders or with a pneumatic rotary indexing table with six holders for rapid printing in two colours.

Available versions include a table-top model, a free-standing model on a base or with a safety cell. Part shuttling can also be used to integrate preparation and finishing work as well as camera controls into the printing process.

ONE SOLUTION – ENDLESS POSSIBILITIES

Are you looking for a cost-efficient solution to meet your needs?

The MS line offers a broad range of configurations to meet your specific needs, ensuring maximum precision, flexibility and versatility.

Introduction video

System options

As part of an overall system with conveyor belt

Including preparation (flame treatment / corona

Rotary index table for pre- & post-treatment

Robot loader

Downloads

MS Line

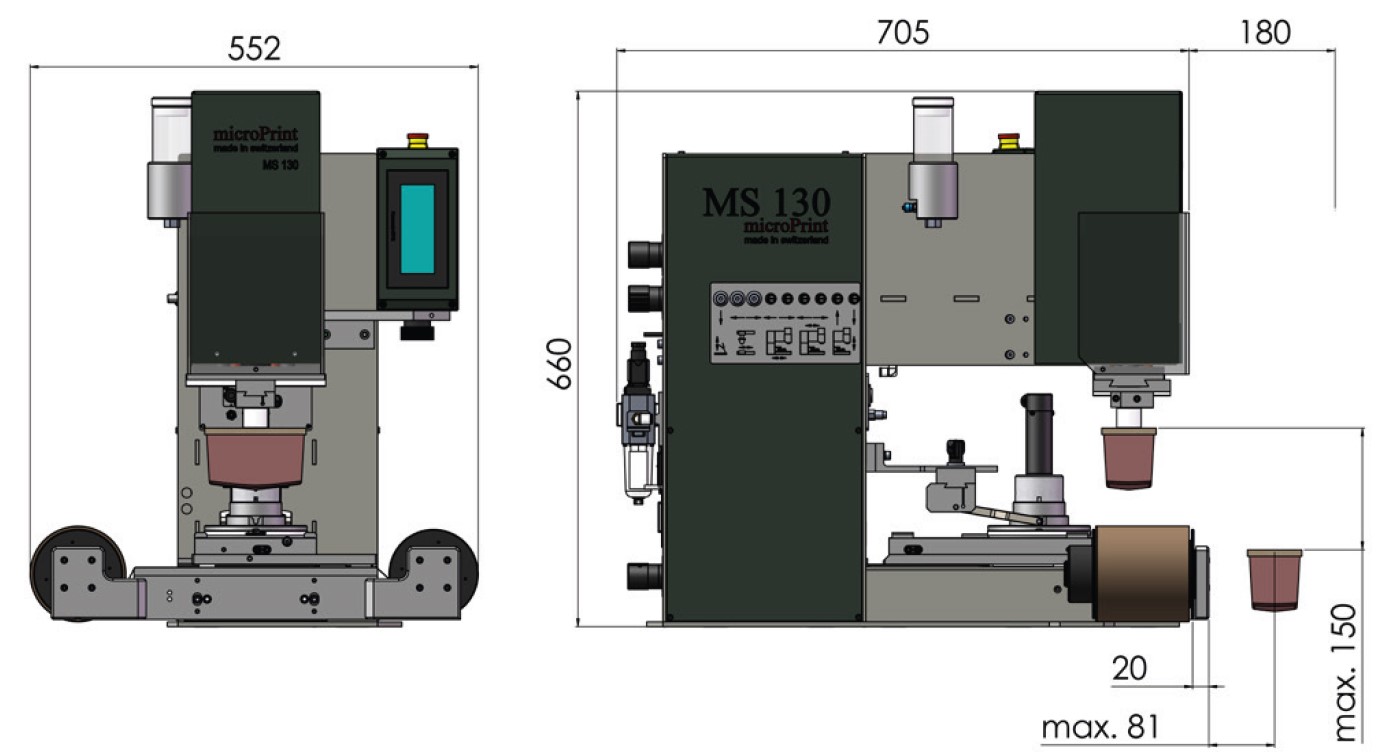

| Machine types | MS 130 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,600/1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 130 x 250 x 10/0,5 |

| Cliché sizes max. open [mm] | 120 x 120 x 10/0,5 |

| Cliché sizes for transverse doctoring unit max. [mm] | - |

| Ink cup [number x Ø in mm] | 1x56 / 1x70 / 1x86 / 1x120 |

| Ink cup oval [mm] | - |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 480 |

| Pad stroke – travel distance max. [mm] | 150 |

| Pad projection max. [mm] | 125 |

| Pad cleaning | optional: 115 mm wide |

| Program memory size | optional: 100 |

| Interfaces | digital interface |

| Thinning system | optional: 1 connection |

| Weight without base [kg] | approx. 75 |

| Air consumption [l/min] | 104 |

| Power supply | 110 – 240V, 50/60Hz |

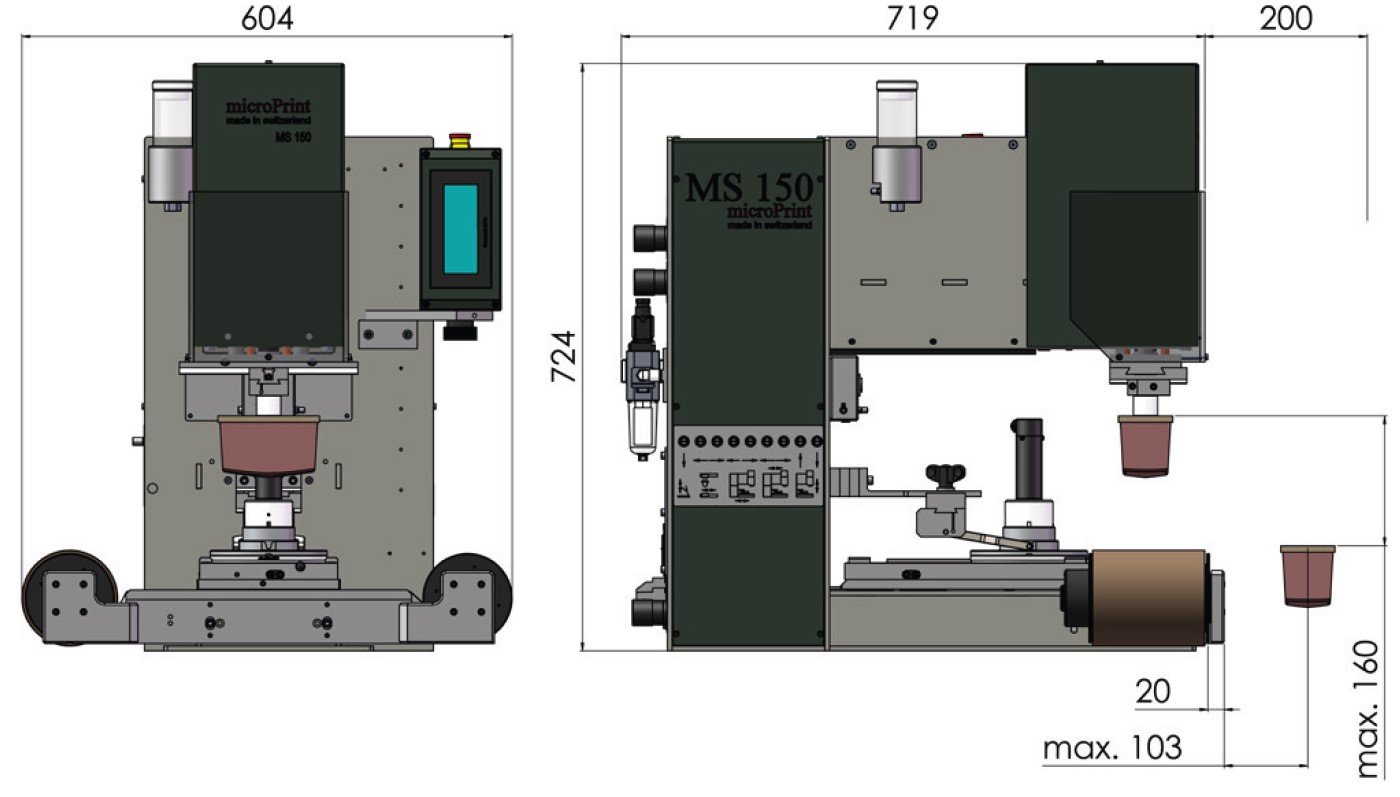

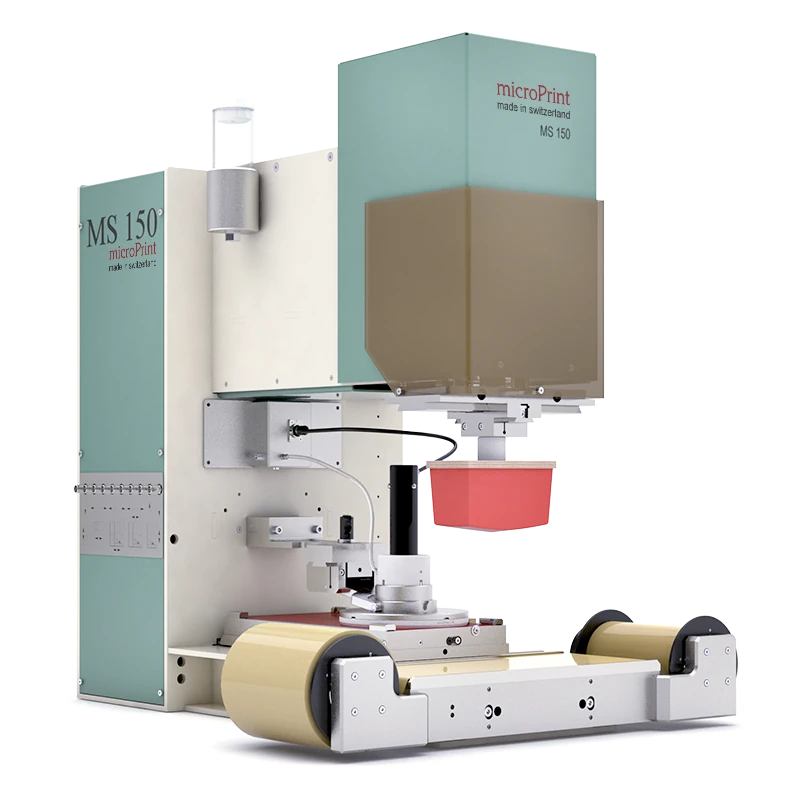

| Machine types | MS 150 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,300/850 with cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 150 x 300 x 10/0,5 |

| Cliché sizes max. open [mm] | on request |

| Cliché sizes for transverse doctoring unit max. [mm] | - |

| Ink cup [number x Ø in mm] | 1x56 / 1x70 / 1x86 / 1x120 / 1x140 |

| Ink cup oval [mm] | - |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 / 130 |

| Pad stroke – force [N] | 1.100 |

| Pad stroke – travel distance max. [mm] | 150 |

| Pad projection max. [mm] | 98 |

| Pad cleaning | optional: 138 mm wide |

| Program memory size | optional: 100 |

| Interfaces | digital interface |

| Thinning system | optional: 1 connection |

| Weight without base [kg] | approx. 97 |

| Air consumption [l/min] | 125 |

| Power supply | 110 – 240V, 50/60Hz |

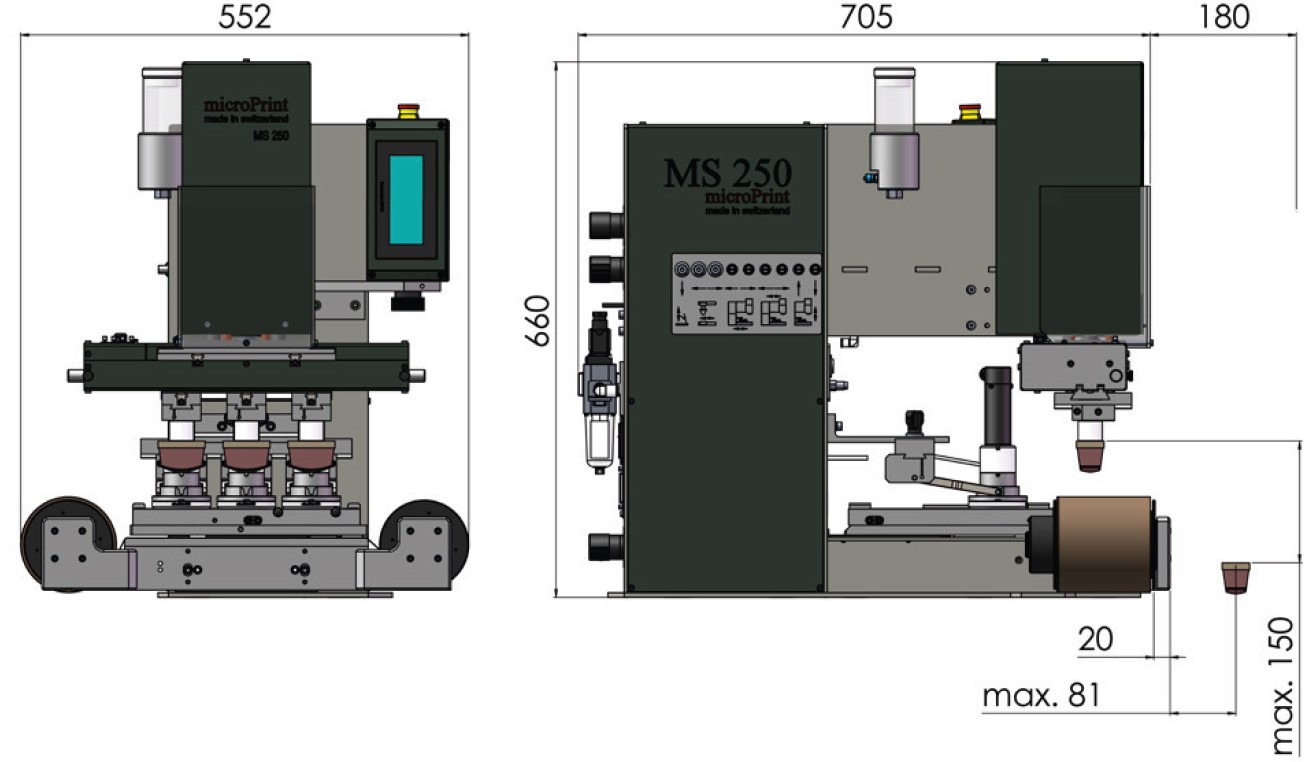

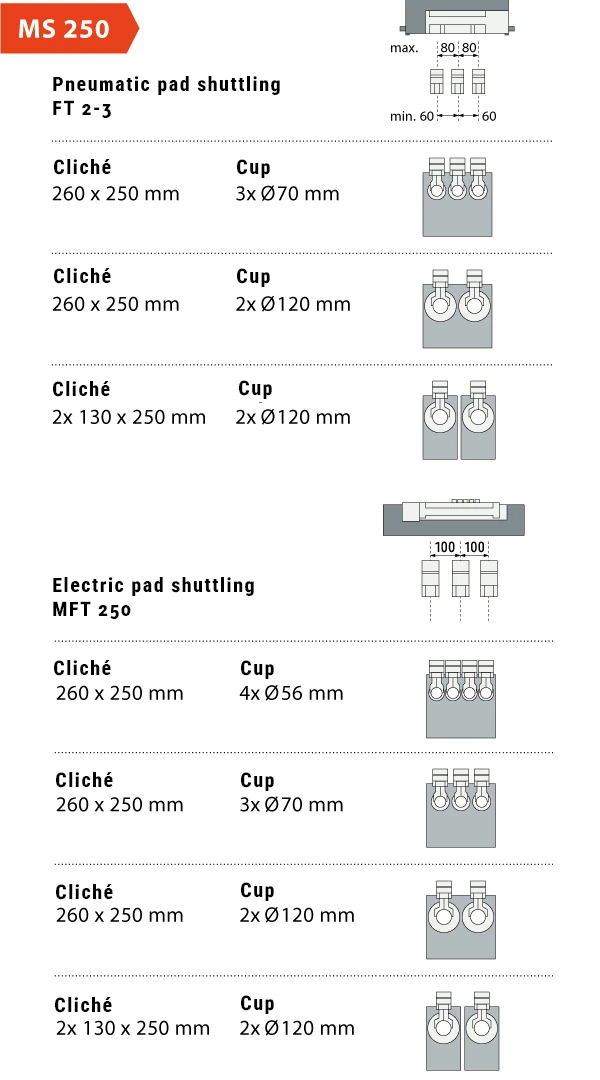

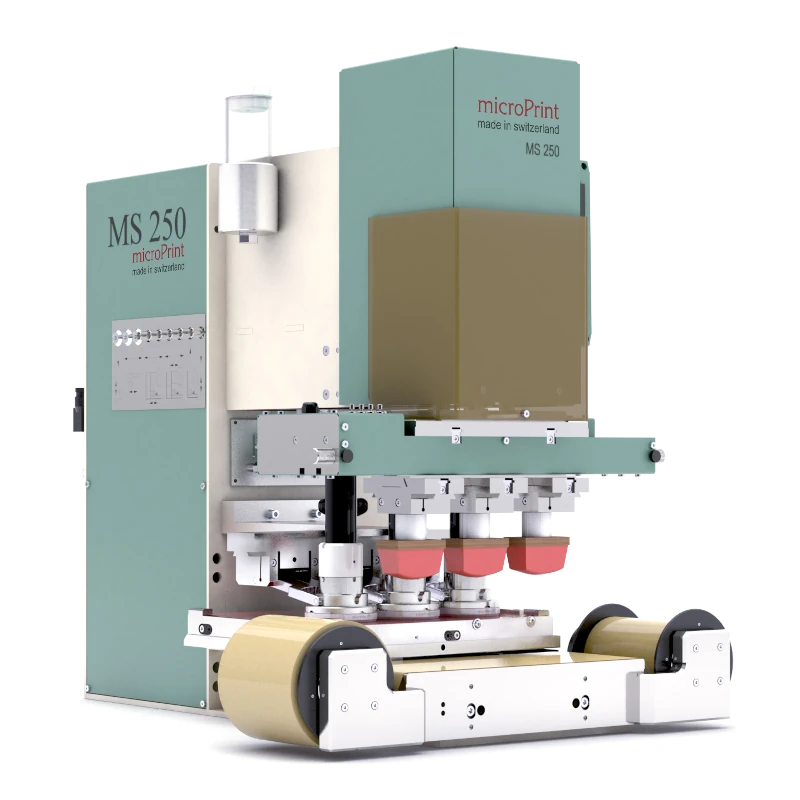

| Machine types | MS 250 |

| Number of colours | 1 - 4 |

| Speed [cycles/h] | 1,500/1,000 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 260 x 250 x 10/0,5 |

| Cliché sizes max. open [mm] | 250 x 120 x 10/0,5 |

| Cliché sizes for transverse doctoring unit max. [mm] | 100 x 430 mm, on request |

| Ink cup [number x Ø in mm] | 4x56 / 3x70 / 2x86 / 2x120 |

| Ink cup oval [mm] | 237 x 68 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 750 |

| Pad stroke – travel distance max. [mm] | 150 |

| Pad projection max. [mm] | 125 |

| Pad cleaning | optional: 115 mm wide |

| Program memory size | optional: 100 |

| Interfaces | digital interface |

| Thinning system | optional: 1–4 connections |

| Weight without base [kg] | approx. 75 |

| Air consumption [l/min] | 110 |

| Power supply | 110 – 240V, 50/60Hz |

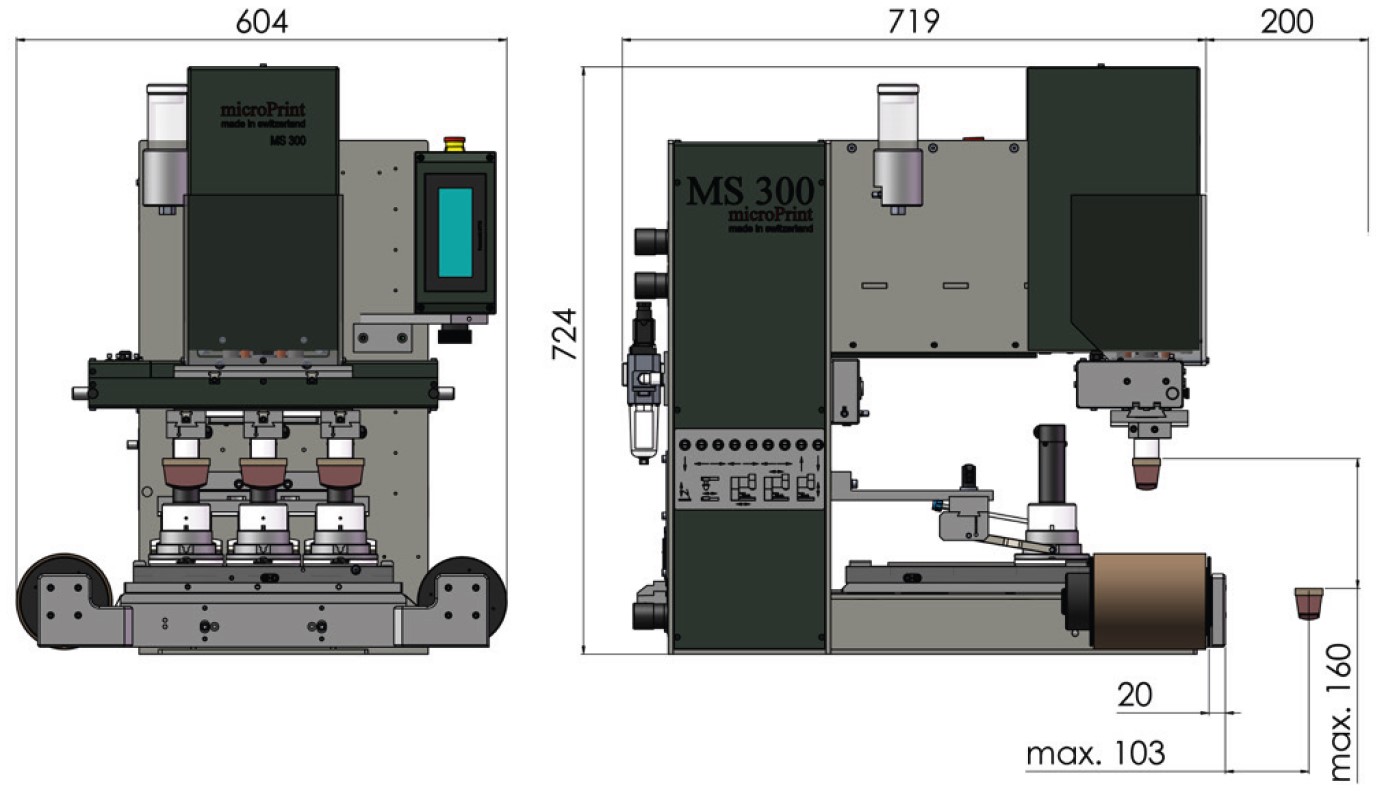

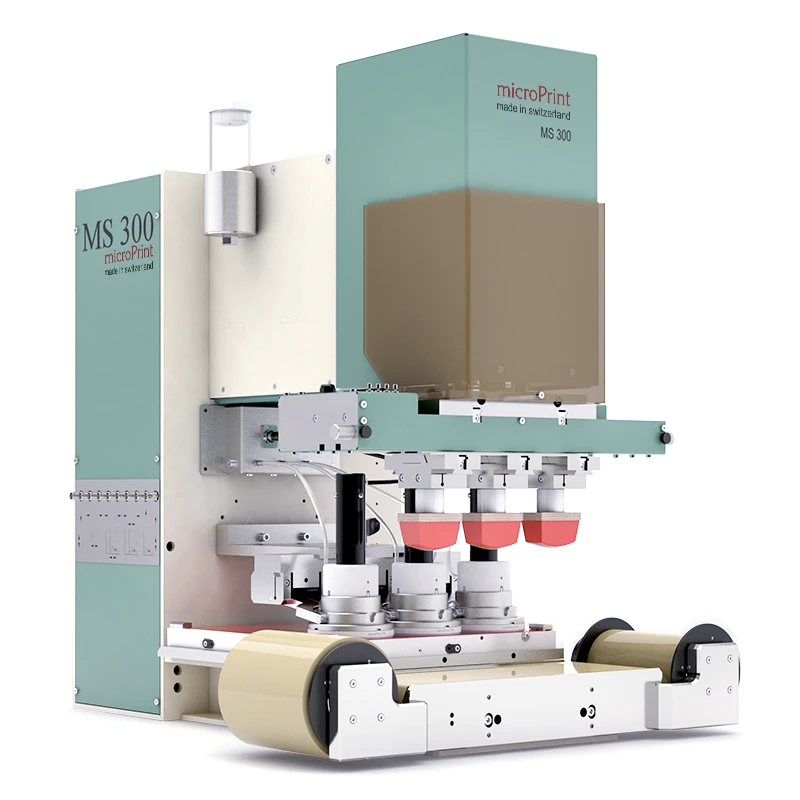

| Machine types | MS 300 |

| Number of colours | 1 - 4 |

| Speed [cycles/h] | 1,300/850 with cleaning |

| Drive – pad stroke | pneumatic |

| Cliché sizes max. [mm] | 300 x 300 x 10/0,5 |

| Cliché sizes max. open [mm] | on request |

| Cliché sizes for transverse doctoring unit max. [mm] | 100 x 500 mm, on request |

| Ink cup [number x Ø in mm] | 4x56 / 4x70 / 3x86 / 2x120 / 2x140 |

| Ink cup oval [mm] | 237 x 68 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 / 130 |

| Pad stroke – force [N] | 1.100 |

| Pad stroke – travel distance max. [mm] | 150 |

| Pad projection max. [mm] | 98 |

| Pad cleaning | optional: 138 mm wide |

| Program memory size | optional: 100 |

| Interfaces | digital interface |

| Thinning system | optional: 1–4 connections |

| Weight without base [kg] | approx. 109 |

| Air consumption [l/min] | 125 |

| Power supply | 110 – 240V, 50/60Hz |