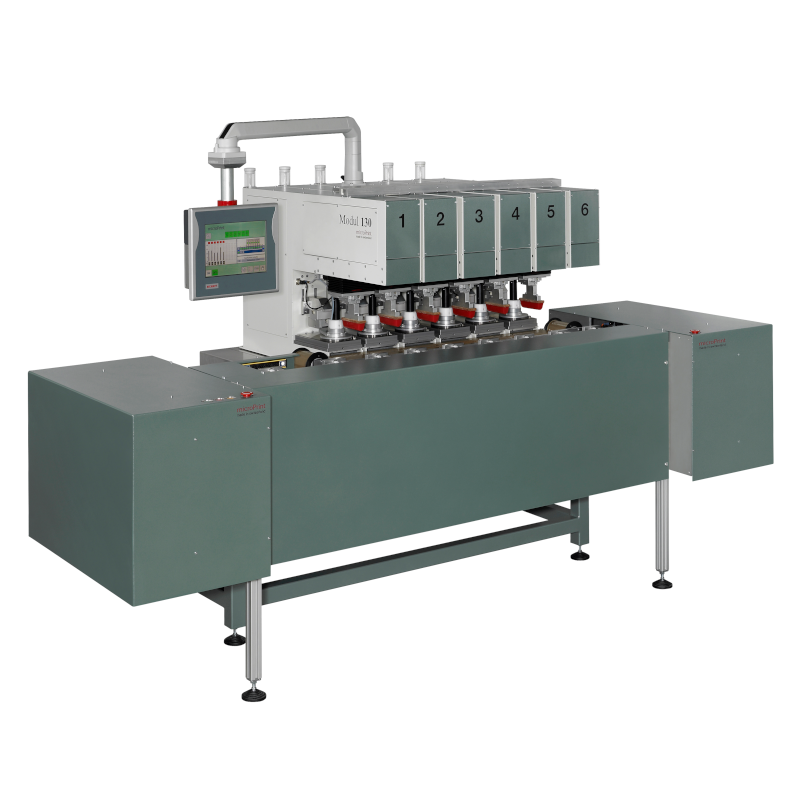

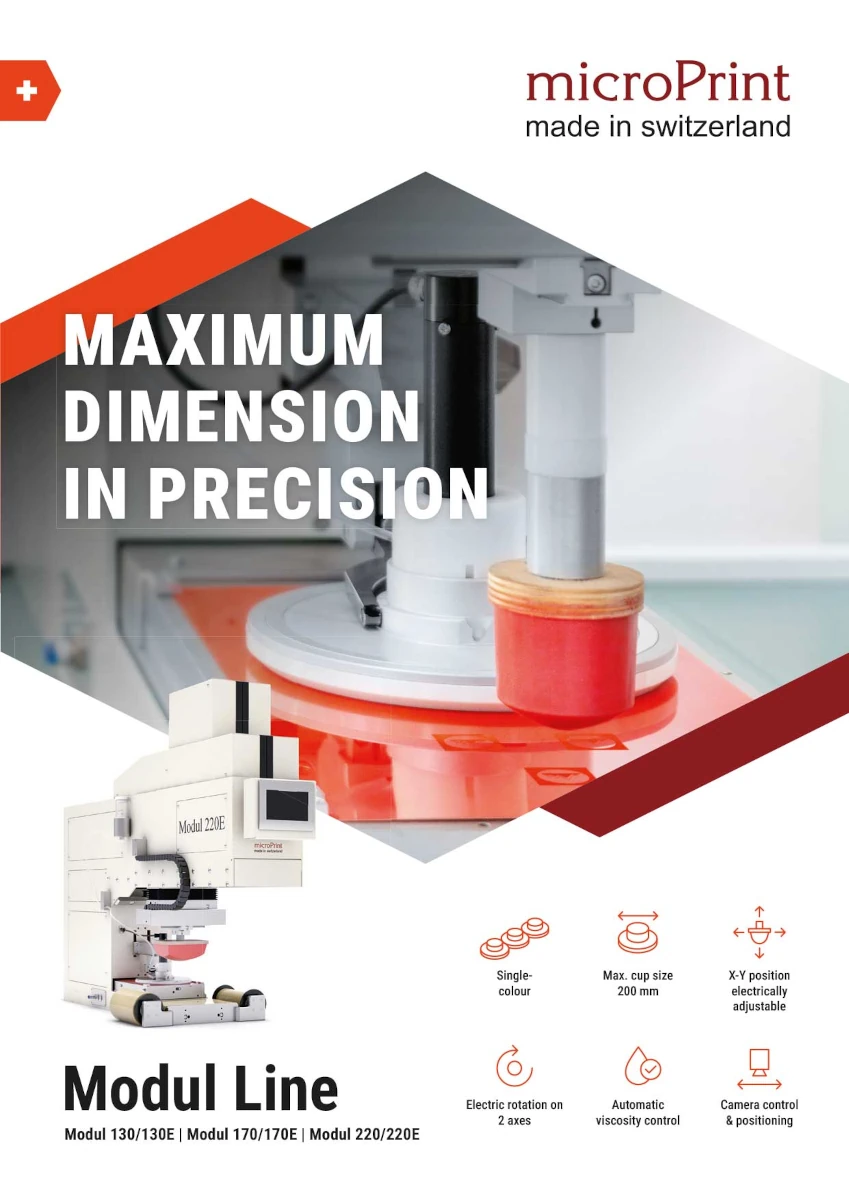

Modul Line

The Modul line features single-coloured pad printing machines with electric positioning and

an optional pneumatic or electric pad stroke. The printing positions are adjusted through the graphic, multicoloured touchscreen display. The printing procedure can be programmed as desired.

It is possible to position many different print images on a single printing cliché.

These can be individually controlled, so that complex composite images or different variations can be printed. Depending on requirements, several machines from the Modul line can be combined into one system and operated using a single display. This means that an almost unlimited number of colours with pot sizes of up to 200 mm are possible. Order data is stored in one central location, which significantly decreases adjustment times. Printing positions can be corrected in real time by camera or through the interface of a superordinate system. There are many options available for parts handling: from pneumatic shuttling up to electric rotation on two axes using vacuum clamps and parts sensors.

Applications

The Modul line is mostly used as a part of larger systems. It is suitable for parts with multiple images printed in various positions as well as for printing different variants within the scope of one single print job. For applications with short cycle times and high precision. Several units on a transport system can print very large quantities in multiple colours in parallel. Large and complex parts can be printed in a single

process using a linear drive with a holder in combination with a rotation device. For sensitive printing processes (including printed electronics, opaque or translucent printing), we recommend using an electrically powered pad stroke.

Inkwell

The machines in the Modul line are single-colour pad printing machines equipped with closed inkwells. The maximum cup size is 200 mm. The surface pressure of the magnetic doctoring cups can be increased by a pneumatic holder on request. If required, it is also possible to equip a special Modul variant with two pots. If the optional microPrint Viscomat is installed, ink viscosity inside the cup is regulated automatically.

Pad positioning

The X and Y positions of the pad are controlled by linear motors. They are adjusted in 0.01 mm increments

using the display. The pad stroke can either be executed pneumatically or electrically using a servomotor

and spindles. In the case of a pneumatic stroke, the speed is controlled using throttles. The electric pad stroke enables the use of different speeds on the up and down stroke for every single step – up to and including setting the length of time the pad remains in contact with the print object. The angle can be adjusted either mechanically or electrically.

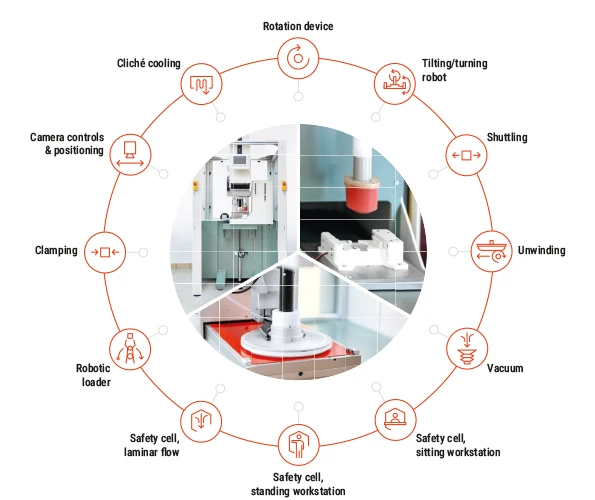

Parts handling

Standard models feature two toolport interfaces for connecting simple handling devices, such as vacuum boxes, parts sensors, clamps, pneumatic shuttle or rotation, or controlled jets of ionised air. The Modul line can be optionally fitted with electrically powered rotation on one or two axes or a simple shuttle for integrating any pre- or post-treatment devices, controls and positioning via cameras, or robotic loaders.

Operation, software and interface

Operation is performed through the graphic, multicoloured touchscreen display. It is possible to operate several units within a system via a single display. Printing procedures can be programmed in simple steps with the help of a user-friendly visual representation. The Modul line features a galvanically isolated digital interface and an Ethernet connection for updates and back-ups of order data. Optional system communication enhancements include Profinet, Ethernet/IP or EtherCAT. To integrate operational data recording, an optional OPC UA interface is available.

Accessories

For standalone operation within a system, we recommend at least pad cleaning control and the Viscomat. For higher requirements regarding product safety, we also offer filling level gauges for both units, as well as additional sensors for temperature and humidity. Cliché cooling is available to minimise temperature effects on colour transfer time and on the ink’s pot life. Safety cells can be specially designed for sitting or standing workstations. They can also be equipped with an additional rotary indexing table and a laminar flow to minimise dust. A barcode reader simplifies and speeds up the set-up process.

ONE SOLUTION – ENDLESS POSSIBILITIES

Are you looking for a tailored solution to meet your needs?

The Modul line offers a broad range of configurations to meet your specific needs, ensuring maximum precision, flexibility and versatility.

Introduction video

System options

Complete system with conveyor belt and camera controls

Large system incorporating multiple units, with shuttle table and central control system

Rotary index table for pre- & post-treatment

Robot loader

Examples

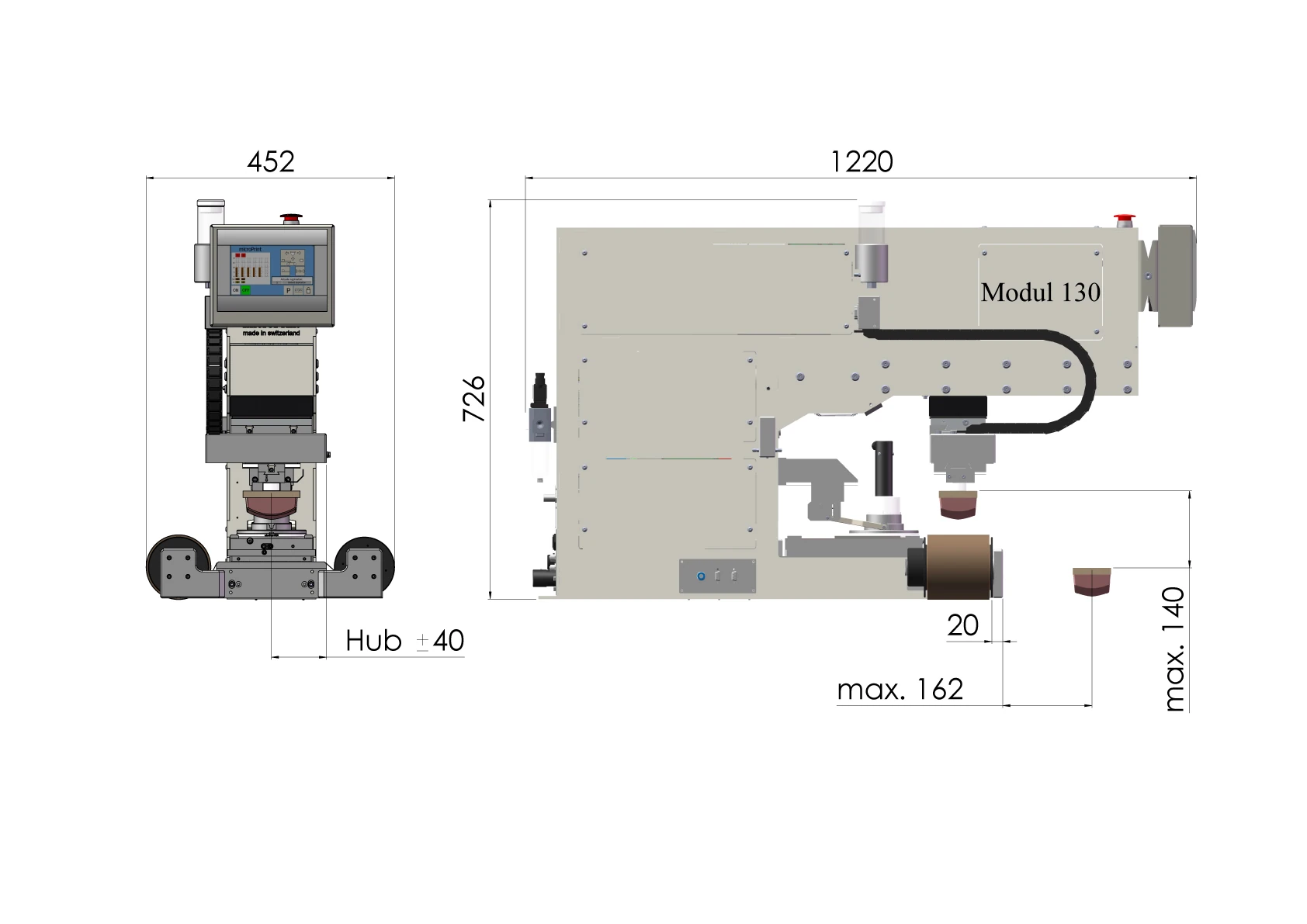

| Machine types | Modul 130 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,800/1,200 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Drive – pad X-axis | Linear motor |

| Drive – pad y-axis | Linear motor |

| Drive – cliché | pneumatic (S) / Linear motor (O) |

| Cliché sizes max. [mm] | 130 x 250 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x56 / 1x70 / 1x86 / 1x120 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 750 |

| Pad stroke – travel distance max. [mm] | 140 |

| Pad projection max. [mm] | 162 |

| Pad cleaning | optional: 115 mm wide |

| Program memory size | approx. 200 |

| Interfaces | digital, Ethernet / optional: EtherCAT, Profinet, Ethernet IP, OPC UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 92 |

| Air consumption [l/min] | 78 |

| Power supply | 110 – 240V, 50/60Hz |

| Modul 130 | |

| |

| Download detailed drawing as PDF | |

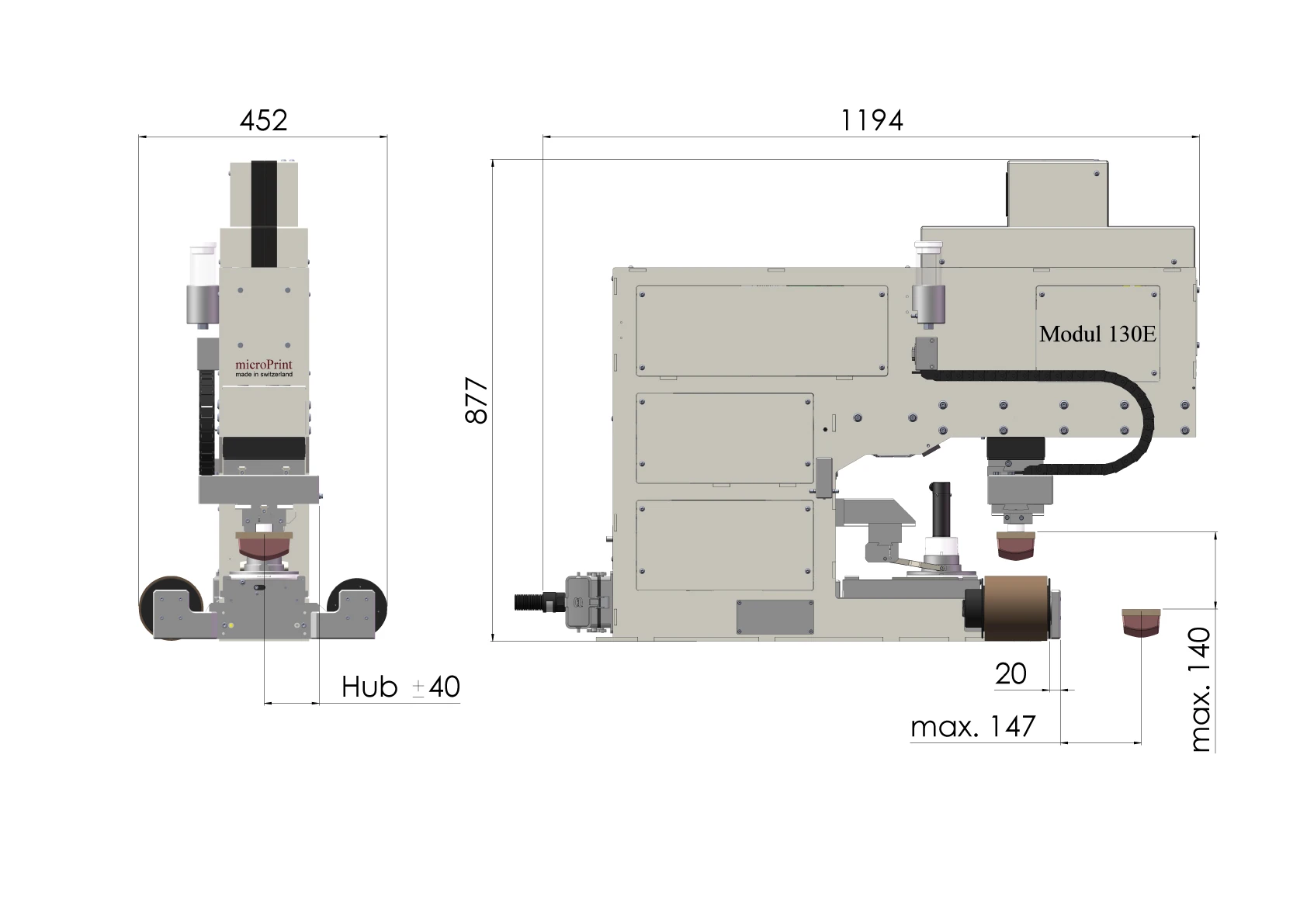

| Machine types | Modul 130E |

| Number of colours | 1 |

| Speed [cycles/h] | 1,900/1,300 with pad cleaning |

| Drive – pad stroke | electric with servo motor |

| Drive – pad X-axis | Linear motor |

| Drive – pad y-axis | Linear motor |

| Drive – cliché | pneumatic (S) / Linear motor (O) |

| Cliché sizes max. [mm] | 130 x 250 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x56 / 1x70 / 1x86 / 1x120 |

| Print image max. [Ø in mm] | 46 / 60 / 76 / 110 |

| Pad stroke – force [N] | 1.000 |

| Pad stroke – travel distance max. [mm] | 140 |

| Pad projection max. [mm] | 147 |

| Pad cleaning | optional: 115 mm wide |

| Program memory size | approx. 200 |

| Interfaces | digital, Ethernet / optional: EtherCAT, Profinet, Ethernet IP, OPC UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 130 |

| Air consumption [l/min] | 48 |

| Power supply | 110 – 240V, 50/60Hz |

| Modul 130E | |

| |

| Download detailed drawing as PDF | |

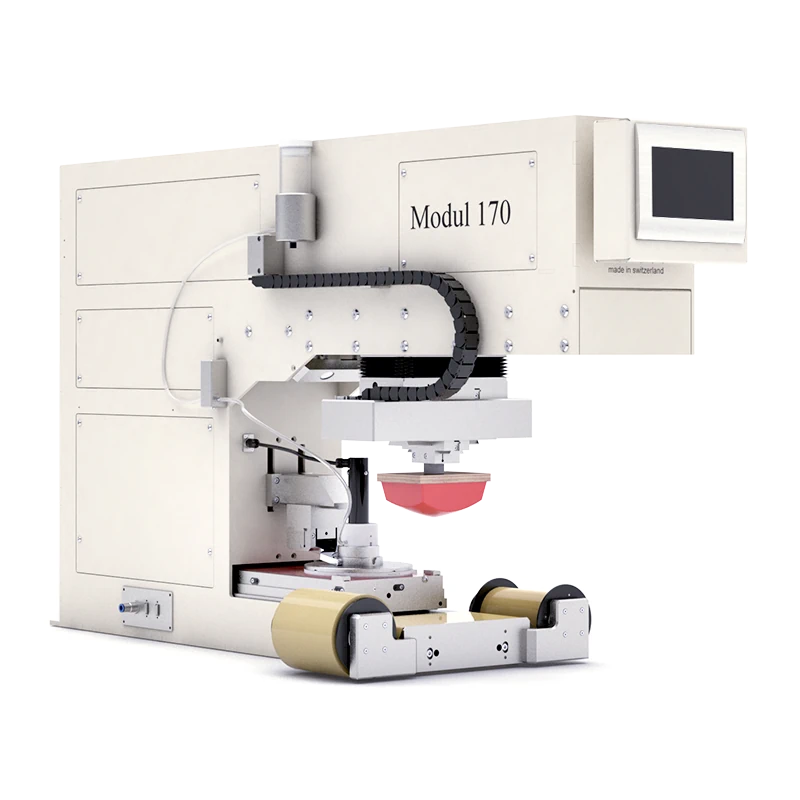

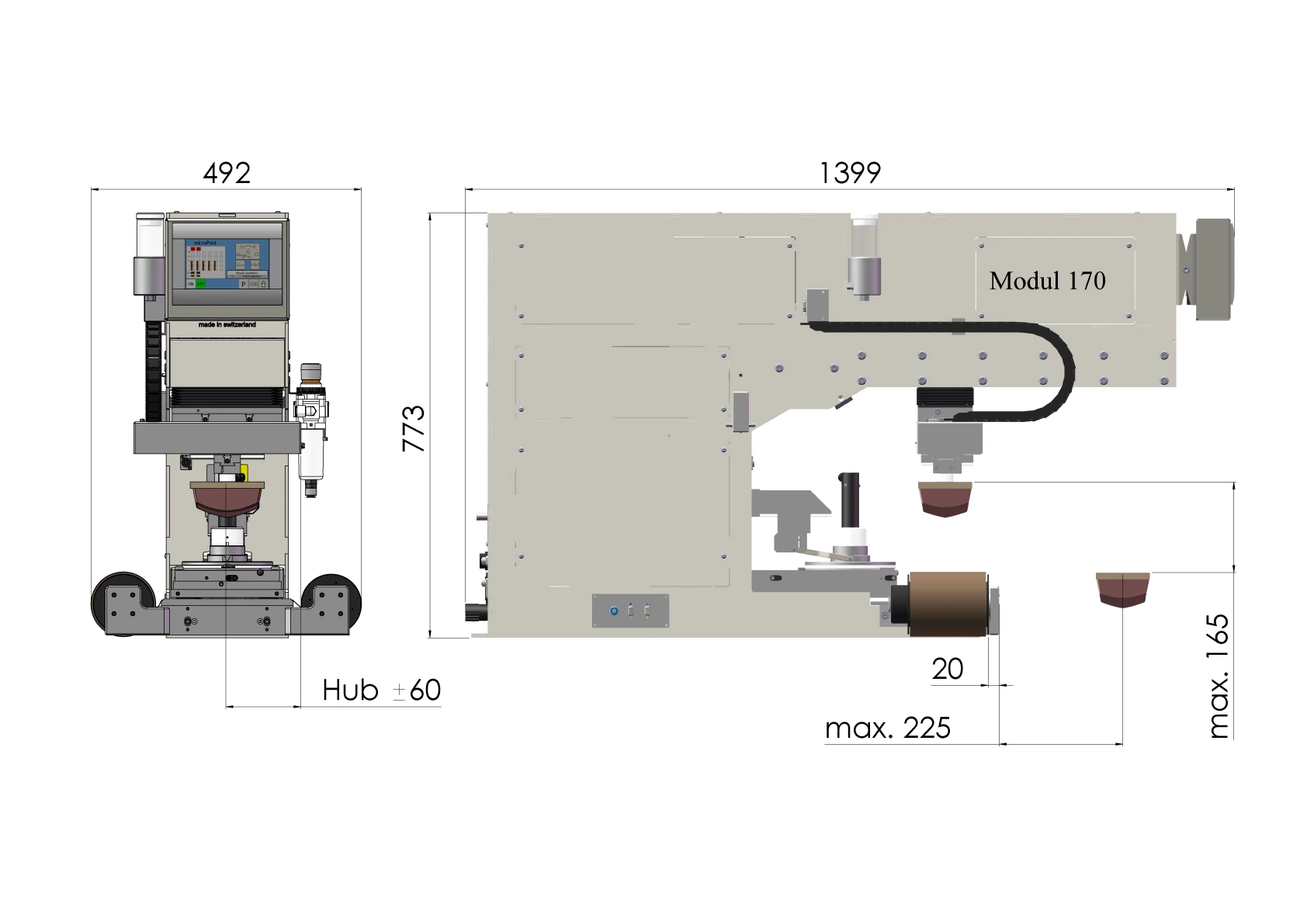

| Machine types | Modul 170 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,600/1,100 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Drive – pad X-axis | Linear motor |

| Drive – pad y-axis | Linear motor |

| Drive – cliché | pneumatic (S) / Linear motor (O) |

| Cliché sizes max. [mm] | 170 x 330 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x120 / 1x140 / 1x160 |

| Print image max. [Ø in mm] | 110 / 130 / 150 |

| Pad stroke – force [N] | 1.750 |

| Pad stroke – travel distance max. [mm] | 1.750 |

| Pad projection max. [mm] | 225 |

| Pad cleaning | optional: 138 mm wide |

| Program memory size | approx. 200 |

| Interfaces | digital, Ethernet / optional: EtherCAT, Profinet, Ethernet IP, OPC UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 159 |

| Air consumption [l/min] | ca. 159 |

| Power supply | 110 – 240V, 50/60Hz |

| Modul 170 | |

| |

| Download detailed drawing as PDF | |

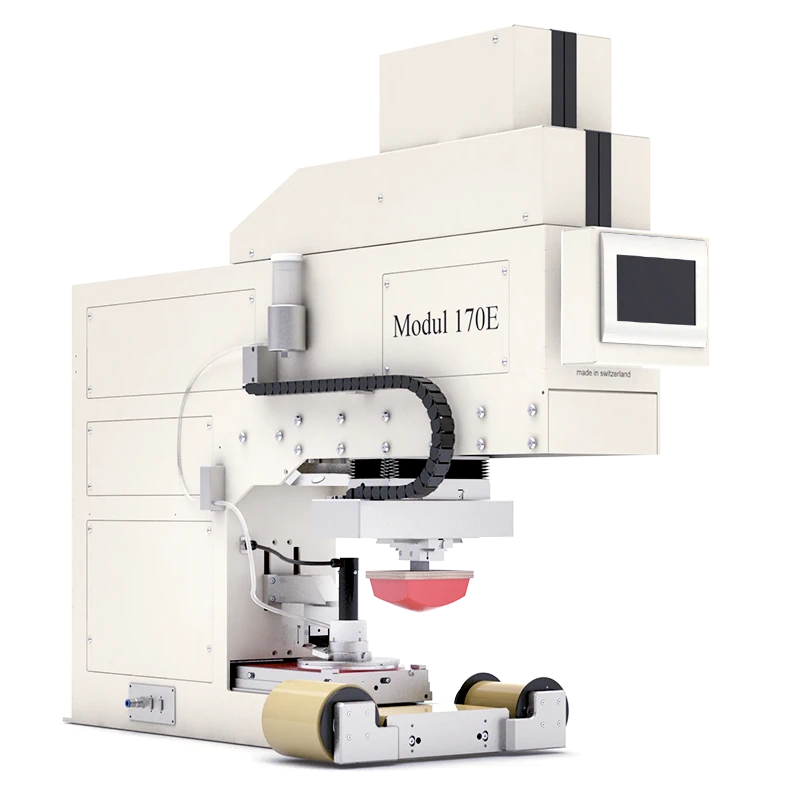

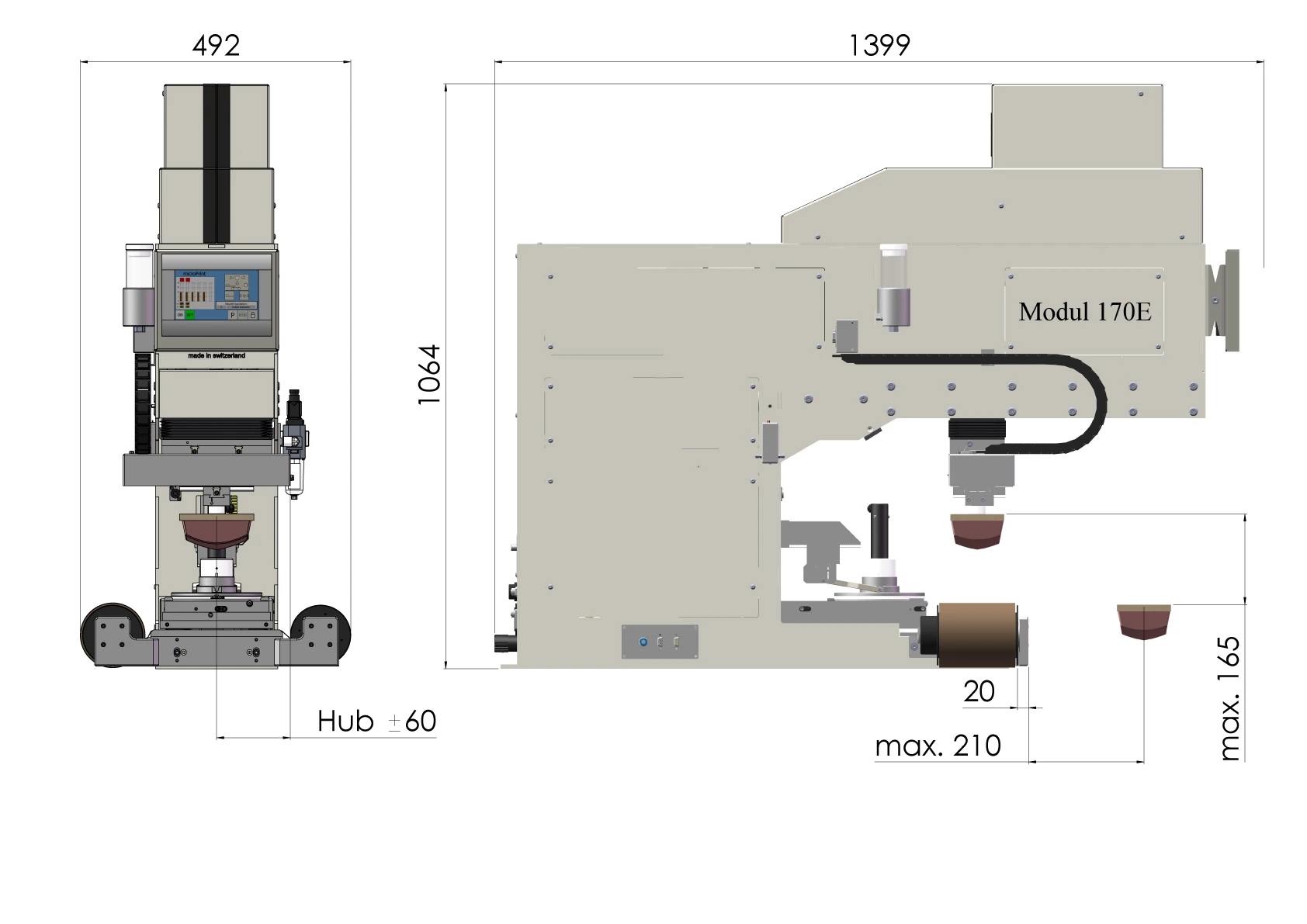

| Machine types | Modul 170E |

| Number of colours | 1 |

| Speed [cycles/h] | 1,700/1,200 with pad cleaning |

| Drive – pad stroke | electric with servo motor |

| Drive – pad X-axis | Linear motor |

| Drive – pad y-axis | Linear motor |

| Drive – cliché | pneumatic (S) / Linear motor (O) |

| Cliché sizes max. [mm] | 170 x 330 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x120 / 1x140 / 1x160 |

| Print image max. [Ø in mm] | 110 / 130 / 150 |

| Pad stroke – force [N] | 3.000 |

| Pad stroke – travel distance max. [mm] | 165 |

| Pad projection max. [mm] | 165 |

| Pad cleaning | optional: 138 mm wide |

| Program memory size | approx. 200 |

| Interfaces | digital, Ethernet / optional: EtherCAT, Profinet, Ethernet IP, OPC UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 189 |

| Air consumption [l/min] | ca. 189 |

| Power supply | 110 – 240V, 50/60Hz |

| Modul 170E | |

| |

| Download detailed drawing as PDF | |

| Machine types | Modul 220 |

| Number of colours | 1 |

| Speed [cycles/h] | 1,500/1,000 with pad cleaning |

| Drive – pad stroke | pneumatic |

| Drive – pad X-axis | Linear motor |

| Drive – pad y-axis | Linear motor |

| Drive – cliché | pneumatic (S) / Linear motor (O) |

| Cliché sizes max. [mm] | 220 x 420 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x140 / 1x160 / 1x180 / 1x200 |

| Print image max. [Ø in mm] | 130 / 150 / 170 / 190 |

| Pad stroke – force [N] | 3.000 |

| Pad stroke – travel distance max. [mm] | 190 |

| Pad projection max. [mm] | 190 |

| Pad cleaning | optional: 138/194 mm wide |

| Program memory size | approx. 200 |

| Interfaces | digital, Ethernet / optional: EtherCAT, Profinet, Ethernet IP, OPC UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 180 |

| Air consumption [l/min] | 270 |

| Power supply | 110 – 240V, 50/60Hz |

| Modul 220 | |

| |

| Download detailed drawing as PDF | |

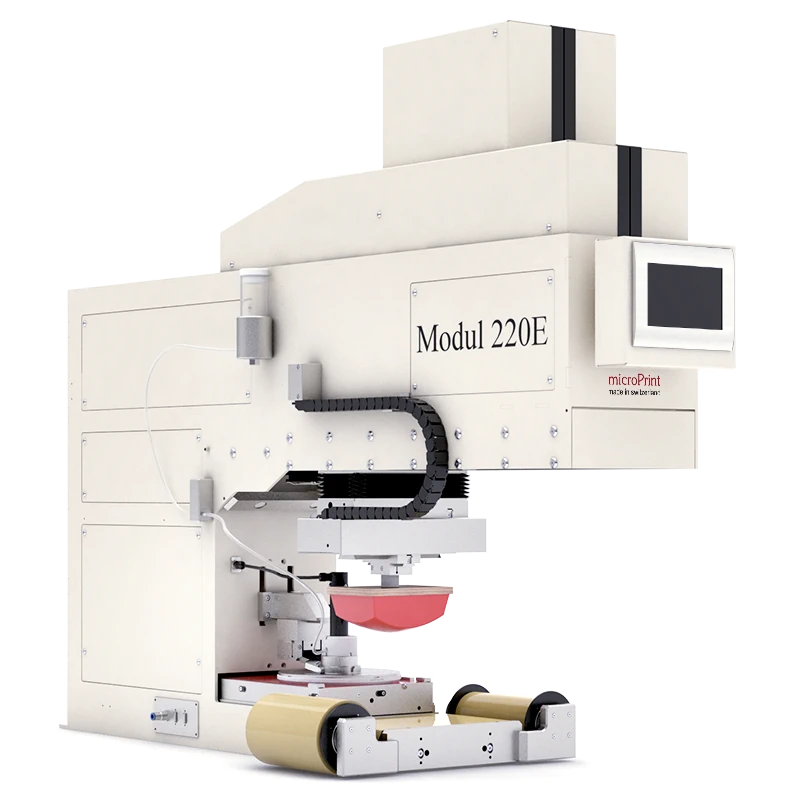

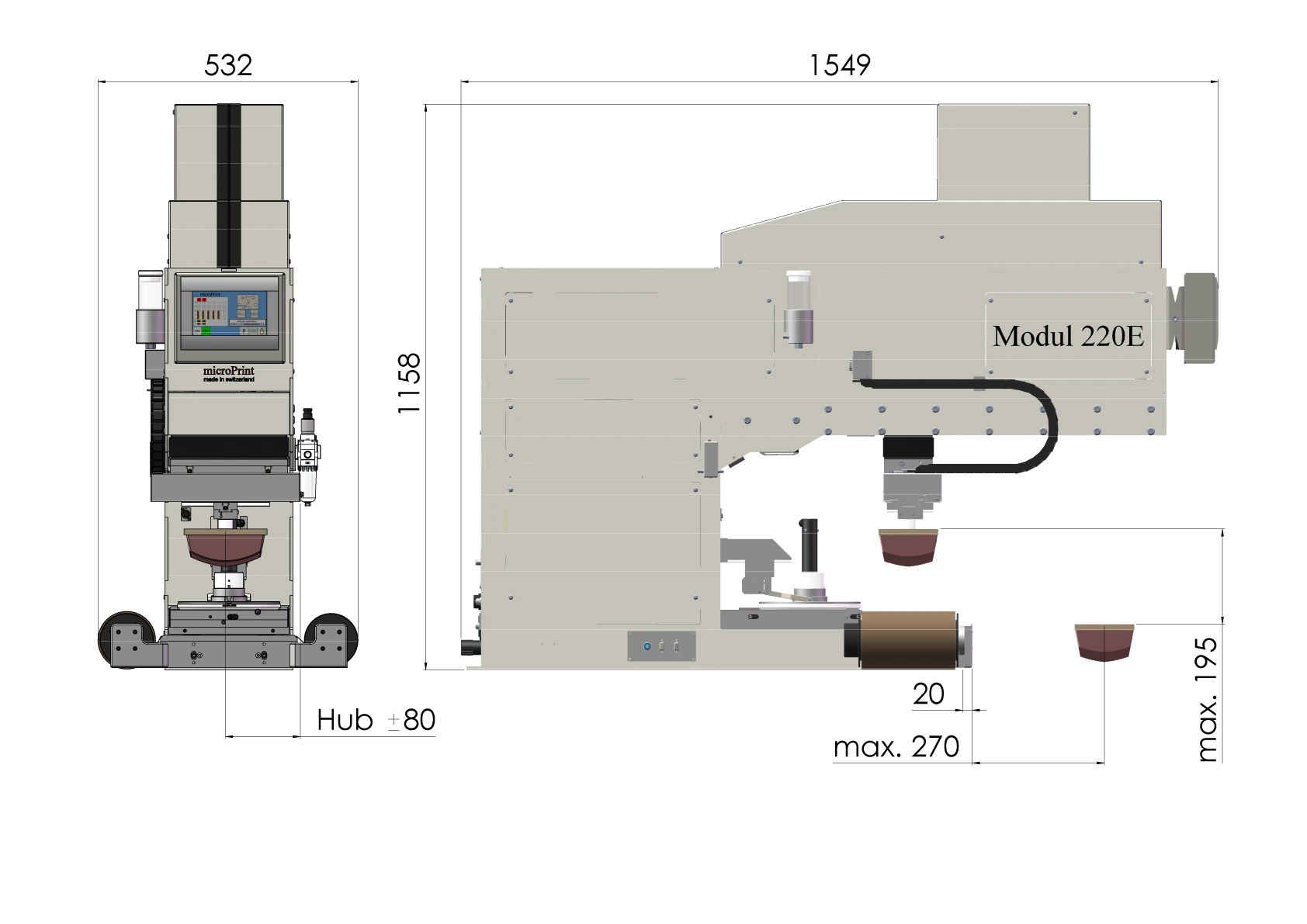

| Machine types | Modul 220E |

| Number of colours | 1 |

| Speed [cycles/h] | 1,600/1,100 with pad cleaning |

| Drive – pad stroke | electric with servo motor |

| Drive – pad X-axis | Linear motor |

| Drive – pad y-axis | Linear motor |

| Drive – cliché | pneumatic (S) / Linear motor (O) |

| Cliché sizes max. [mm] | 220 x 420 x 10/0,5 |

| Ink cup [number x Ø in mm] | 1x140 / 1x160 / 1x180 / 1x200 |

| Print image max. [Ø in mm] | 130 / 150 / 170 / 190 |

| Pad stroke – force [N] | 6.000 |

| Pad stroke – travel distance max. [mm] | 180 |

| Pad projection max. [mm] | 270 |

| Pad cleaning | optional: 138/194 mm wide |

| Program memory size | approx. 200 |

| Interfaces | digital, Ethernet / optional: EtherCAT, Profinet, Ethernet IP, OPC UA |

| Thinning system | optional |

| Weight without base [kg] | approx. 215 |

| Air consumption [l/min] | 130 |

| Power supply | 110 – 240V, 50/60Hz |

| Modul 220E | |

| |

| Download detailed drawing as PDF | |