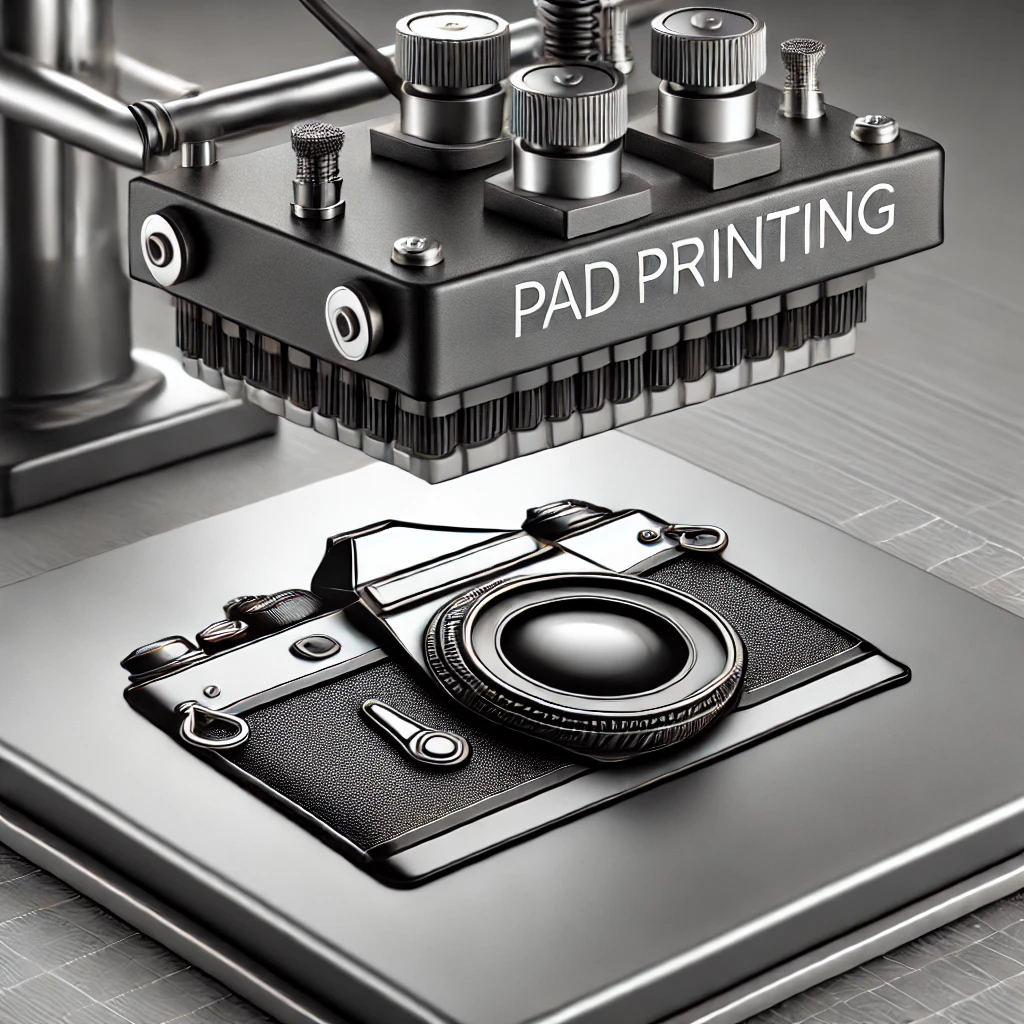

Pad printing

Camera Applications in Pad Printing

Camera systems in the industrial sector have made great advances thanks to AI and electric zoom. What tasks can they perform in pad printing, such as quality control or positioning?

Industry 4.0 in Pad Printing

Industry 4.0 marks the next stage of industrialization. How is it implemented in pad printing? What has already been achieved, and what’s planned for the future?

Industries

Industries

![[Translate to Englisch:] Medizinaltechnik [Translate to Englisch:] Medizinaltechnik](/fileadmin/user_upload/microprint/branchen/medizinaltechnik.jpg)

Medical technology

Pad printing in medical technology is usually carried out under cleanroom conditions. In addition to plastic components such as syringes, device housings, fixators, and microtiter plates, flexible stoma bags and catheters are also printed.

Automotive

The automotive industry places various demands on pad printing with parts such as Isofix, fuel filler caps, engine covers, wheel rims and backlit dashboards. Error prevention is essential here.

![[Translate to Englisch:] Uhrenindustrie [Translate to Englisch:] Uhrenindustrie](/fileadmin/user_upload/microprint/branchen/uhrenindustrie_.jpg)

Watches

The watch industry is the original sector of pad printing. Watch parts such as dials, complications and glass backs are finished with it. Precise machines are essential to guarantee high quality.

![[Translate to Englisch:] Kunststoffindustrie [Translate to Englisch:] Kunststoffindustrie](/fileadmin/user_upload/microprint/branchen/kunststoffindustrie_start_neu.jpg)

Plastic Industry

The printing of plastic parts is the main application of pad printing. The trend is moving towards direct printing at the injection molding machine, with part handling directly managed by the unloading robot.