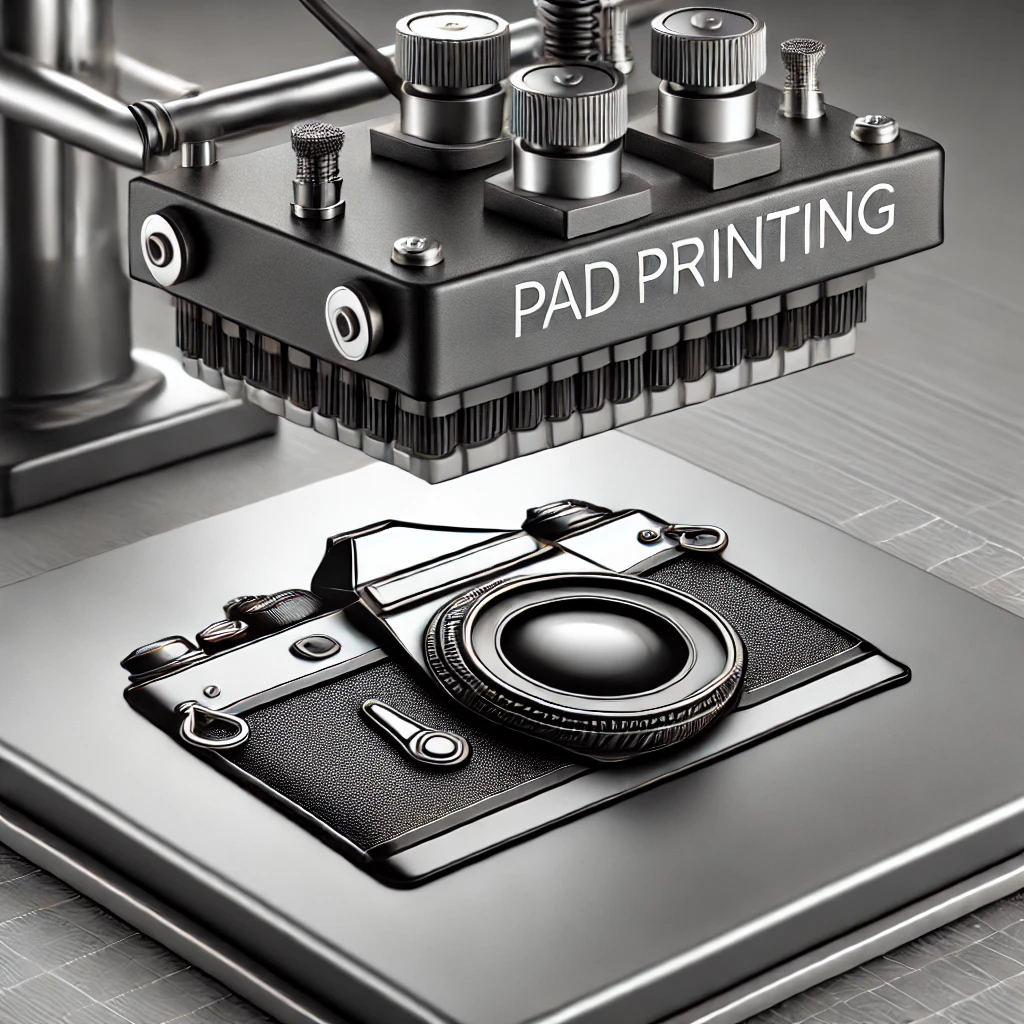

Pad printing

What is pad printing?

Pad printing is a printing process that enables the precise decoration of a wide range of shapes, materials, and surface textures. The print image is etched as a fine depression into a plate known as the cliché. During the printing process, ink is applied to the cliché, filling the depressions of the image. Excess ink is removed using a ring-shaped or straight doctor blade, leaving ink only in the etched areas. A silicone rubber pad—giving the process its name—is then used to pick up the ink from the cliché. The pad moves to the object to be printed and transfers the ink accurately onto its surface. The key advantage of pad printing lies in the flexibility of the pad during the transfer process, which allows for reliable printing on uneven or complex surfaces. The process enables the reproduction of very fine details without the need for halftoning, as the exact color is applied directly. This results in excellent print quality, as required, for example, in the watchmaking industry—where pad printing originated. Further information can be found in our pad printing book.

Pad printing blog

Pad printing blog

Camera Applications in Pad Printing

Camera systems in the industrial sector have made great advances thanks to AI and electric zoom. What tasks can they perform in pad printing, such as quality control or positioning?