Pad printing machines by microPrint

Since 1995, microPrint LC GmbH has been developing and producing pad printing machines in Switzerland, setting new standards and revolutionizing the pad printing process. Our experienced team works with passion and dedication to create innovative technologies that meet the high demands of our customers.

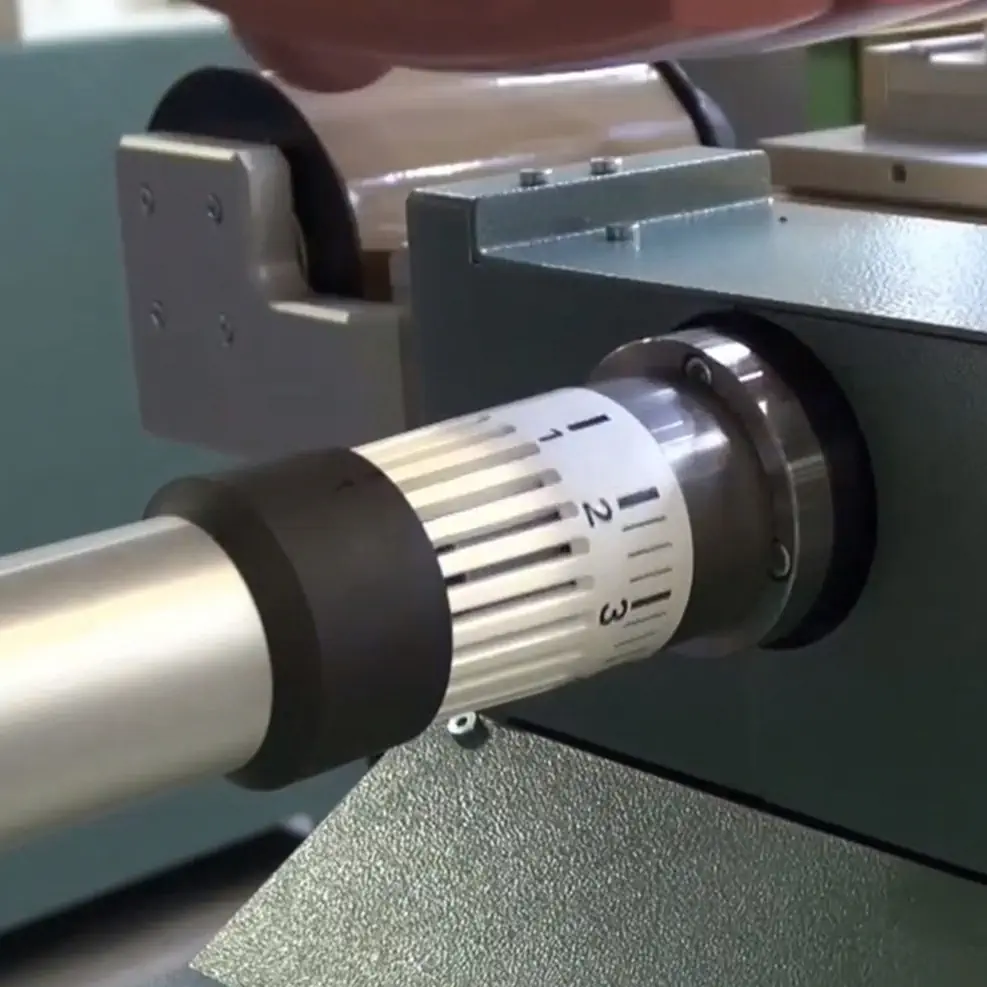

We offer a wide range of standard machines – from simple pneumatic pad printing machines to fully electric systems with freely programmable processes and precise control of tampon stroke speed. In addition, we design customized pad printing machines and implement automation solutions with integrated transport systems and pre- and post-treatment modules.

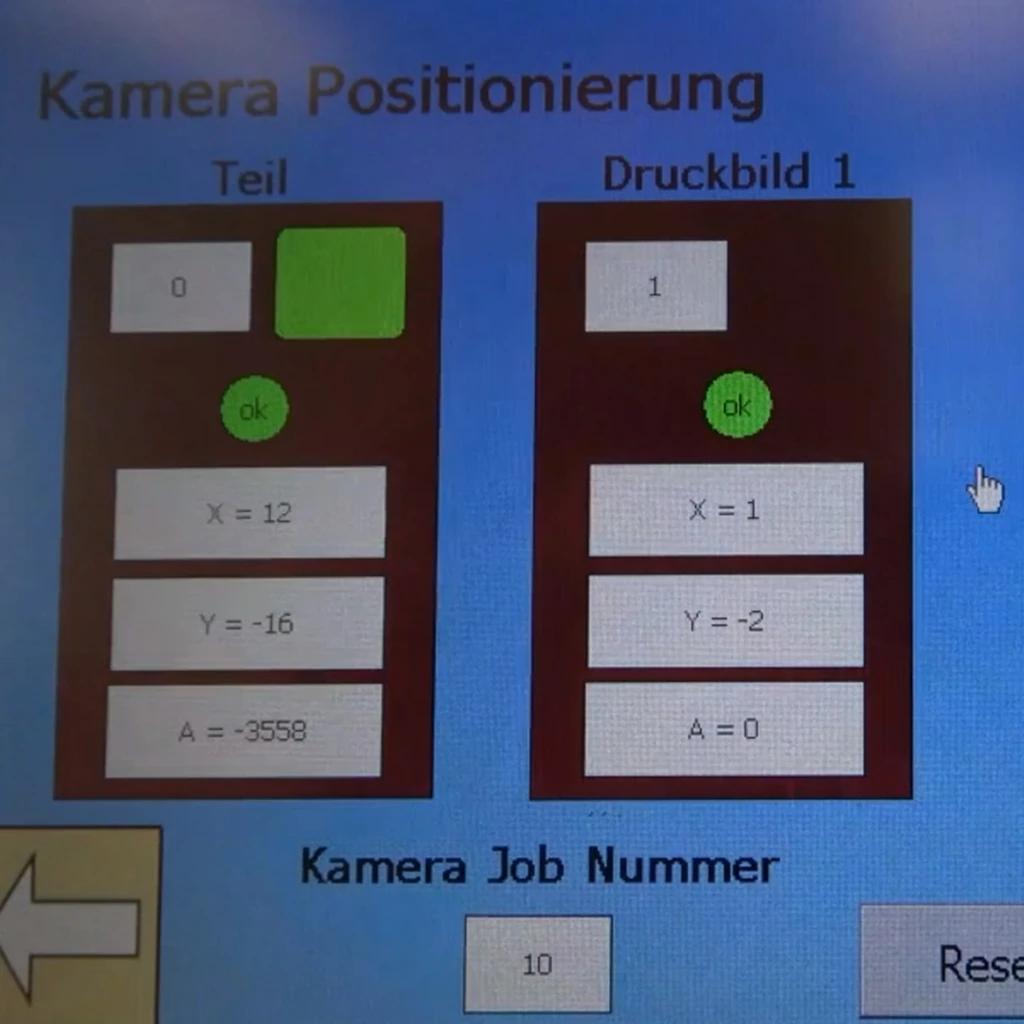

Depending on the application, our machines can be equipped with advanced features such as automatic ink dilution, customized part holders, rotary devices, cliché cooling, or laminar flow systems. The printing process can also be monitored with cameras, and printing positions can be automatically corrected to ensure maximum precision.

Our team of experts is always available to answer your questions about pad printing. We are happy to develop the entire printing process for you and produce sample parts exactly according to your specifications.

Products

Pad Printing Machines

We cover the full range – from pneumatic entry-level models to fully electric high-end systems with freely programmable workflows and precise control of pad stroke speed.

Pad Printing Systems

We combine our pad printing machines with various transport systems and integrate pre- and post-treatment units as well as camera inspection to create semi- or fully automated pad printing systems.

Pad Printing Accessories

Pre-treatment units for reducing surface tension, drying systems for fast ink curing, and cleaning devices using solvent-free cleaning agents – all available here.

Services

![[Translate to :] Offertanfrage [Translate to :] Offertanfrage](/fileadmin/user_upload/dienstleistungen/offertanfrage.jpg)

Quotation request

Do you have a pad printing application and need the right machine? Let’s discuss your requirements in detail and create a tailor-made offer together!

Pad Printing Consultation

Do you need external support for implementing a pad printing application? Benefit from our many years of experience across a wide range of industries.

Sample printing

Do you need to assess the feasibility of a challenging pad printing application? We have state-of-the-art pad printing machines available for sample printing. Put us to the test!

Pad printing blog

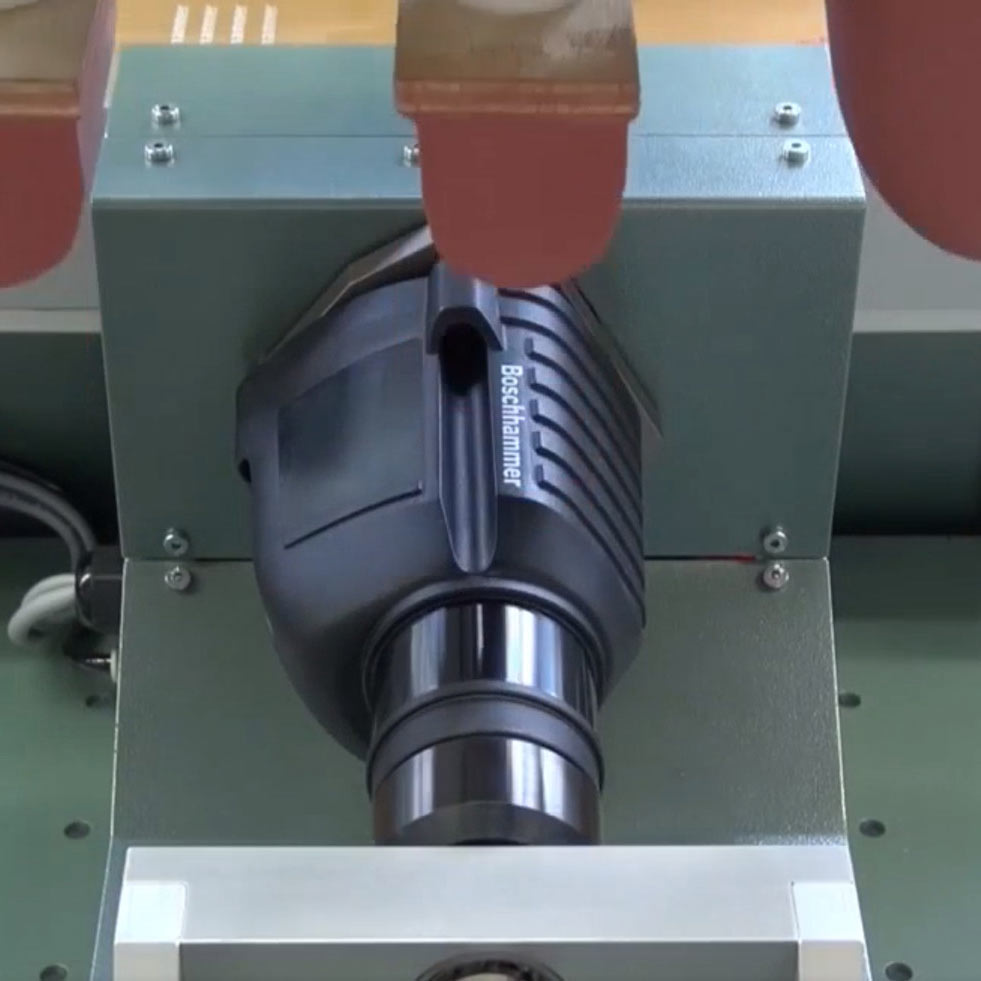

Camera

Camera systems in the industrial sector have made great advances thanks to AI and electric zoom. What tasks can they perform in pad printing, such as quality control or positioning?

Industry 4.0

Industry 4.0 marks the next stage of industrialization. How is it implemented in pad printing? What has already been achieved, and what’s planned for the future?

Ink transfer time

The color transfer time is the shortest interval from the moment of pickup to the complete color transfer by the pad and is the most important measurement parameter in pad printing.

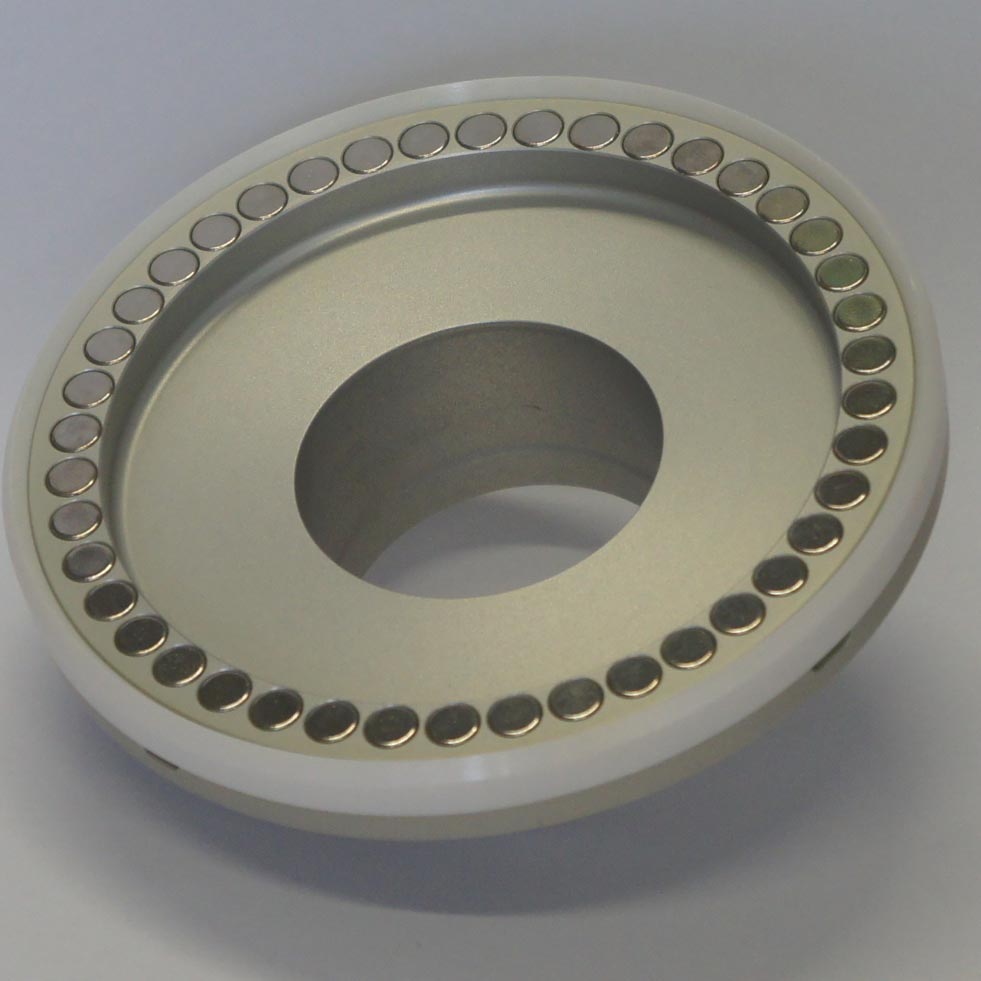

Doctor Ring

Doctoring rings for ink cups vary in material and finish. Which ring suits which pad printing application, and how can it be maintained to extend its lifespan?

Industries

Medical technology

Pad printing in medical technology is usually carried out under cleanroom conditions. In addition to plastic components such as syringes, device housings, fixators, and microtiter plates, flexible stoma bags and catheters are also printed.

Automotive Industry

The automotive industry places various demands on pad printing with parts such as Isofix, fuel filler caps, engine covers, wheel rims and backlit dashboards. Error prevention is essential here.

Watches

The watch industry is the original sector of pad printing. Watch parts such as dials, complications and glass backs are finished with it. Precise machines are essential to guarantee high quality.

Plastic Industry

The printing of plastic parts is the main application of pad printing. The trend is moving towards direct printing at the injection molding machine, with part handling directly managed by the unloading robot.